In the realm of laboratory equipment, precision and efficiency are paramount. The 20l short path distillation kit has emerged as a groundbreaking solution, redefining the landscape of chemical and biological pharmaceutical processes. With its innovative design and exceptional capabilities, this system has found applications across industries, providing a new standard for distillation and extraction procedures.

Introduction to Short Path Distillation System

The short path distillation system, a marvel of engineering, offers an advanced method for separating components from liquid mixtures based on their boiling points. Unlike traditional distillation methods, this system operates at significantly reduced pressures, minimizing the temperature required for separation. This process prevents compound degradation and enhances purity, making it ideal for delicate substances like essential oils, cannabinoids, and fragrance compounds.

Advantages and Applications

The short path distillation system revolutionizes separation techniques with a spectrum of advantages that cater to multifaceted industries. Its ability to achieve unparalleled levels of precision in a single pass sets a new benchmark for efficiency. By operating under reduced pressures, this system preserves the delicate nature of compounds, making it a cornerstone in fields spanning pharmaceuticals, flavors, and fragrances.

In pharmaceuticals, the system’s low-temperature distillation is a game-changer, ensuring the integrity of active ingredients that are otherwise vulnerable to heat. Similarly, in flavor and fragrance production, it unlocks a new realm of possibilities, capturing the most intricate notes of aromas. Its versatility extends to cannabinoid extraction, where maintaining compound potency is paramount.

The short path distillation system redefines the possibilities of separation, fostering innovation across industries and delivering results of unmatched purity and quality.

A Real-world Application: Essential Oil Extraction

In the realm of botanical wonders, essential oils stand as fragrant testaments to nature’s essence. Harnessing the power of the short path distillation system, we unlock a transformative approach to essential oil extraction that safeguards their integrity and potency.

Consider the delicate petals of lavender, rich with aromatic potential. Traditional extraction methods, often involving high temperatures and extended processing times, can compromise the very essence we seek to capture. Enter the short path distillation system, a game-changer in the world of essential oil extraction.

In this innovative process, lavender blooms are gently introduced to the system. As heat is applied to the mixture, compounds begin their journey towards separation. Unlike conventional methods, the short path distillation system operates at reduced pressures, enabling distillation at lower temperatures. This not only ensures the preservation of delicate aromatic molecules but also minimizes the risk of thermal degradation.

As the mixture traverses the distillation column, the magic unfolds. The vapor travels a short path, preventing prolonged exposure to heat and ensuring swift condensation in the cooling condenser. This condensed vapor, now transformed into precious essential oil, is collected with utmost care.

The result? Lavender essential oil of unparalleled quality and potency. The short path distillation system’s ability to preserve volatile compounds makes it an invaluable asset in the realm of essential oils. Whether extracting lavender’s calming essence or capturing the invigorating scent of citrus fruits, this system champions the integrity of botanical wonders, enriching our lives one drop at a time.

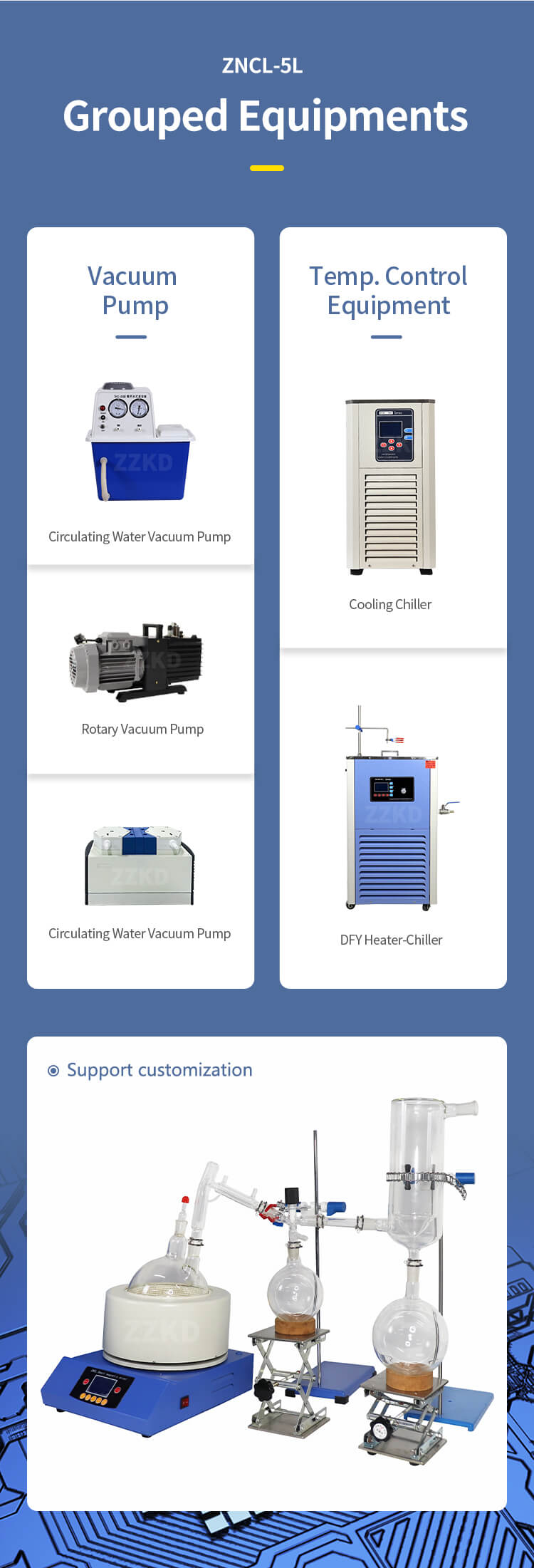

Key Components and Working Principle

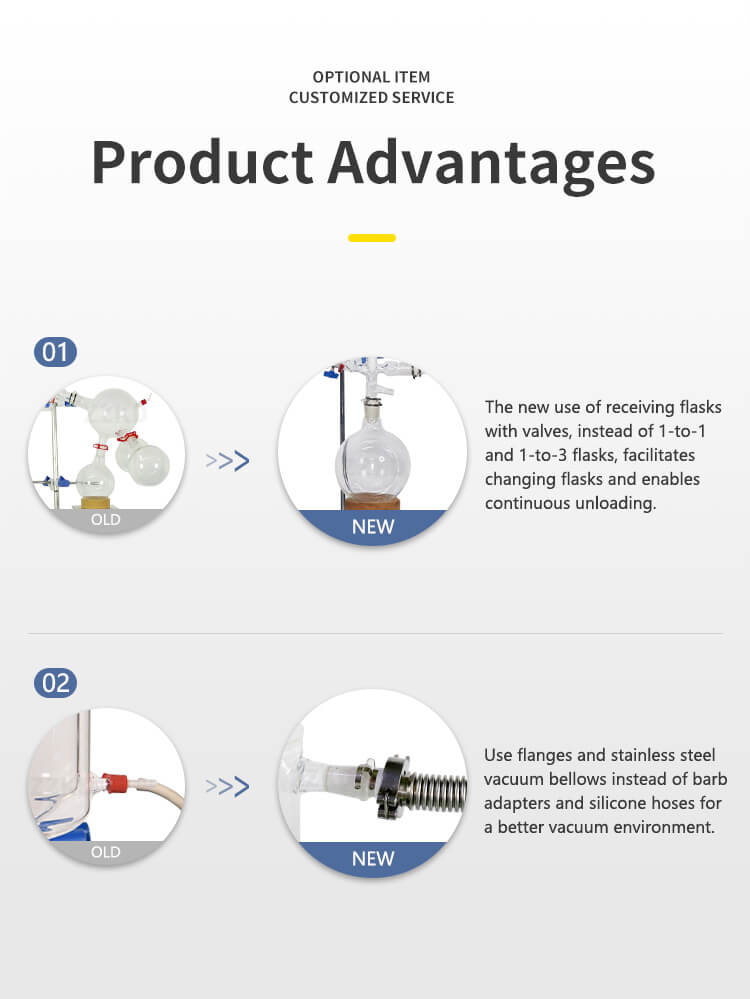

The heart of the short path distillation system lies in its components, each playing a vital role in achieving separation. The setup comprises a heating flask, a distillation column, a cooling condenser, and a receiving flask. The mixture is heated in the flask and then directed through the distillation column, where the vapor travels a short path, ensuring minimal loss. The vapor then condenses in the cooling condenser before being collected in the receiving flask. This streamlined process drastically reduces exposure to high temperatures, preserving the integrity of the compounds.

Ensuring Quality Results: Maintenance and Best Practices

Maintaining a short sath distillation system is crucial to ensuring consistent and reliable results. Regular cleaning of the components, such as the distillation column and condenser, prevents residue buildup that can impede efficiency. Additionally, routine checks of vacuum levels and temperature settings are essential for precise separation. Adhering to these practices guarantees that the system continues to deliver optimal performance and maintains the integrity of the final product.

In conclusion, the short path distillation system stands as a testament to the continuous evolution of laboratory equipment. Its revolutionary approach to precision separation has propelled it into various industries, offering solutions that elevate the quality and efficiency of distillation and extraction processes. With its ability to preserve heat-sensitive compounds, exemplified by its application in essential oil extraction, this system is reshaping the way we approach separation methods. By understanding its key components and adhering to best practices, laboratories can harness the power of this system to achieve exceptional results, solidifying its role as a game-changer in the realm of laboratory equipment.