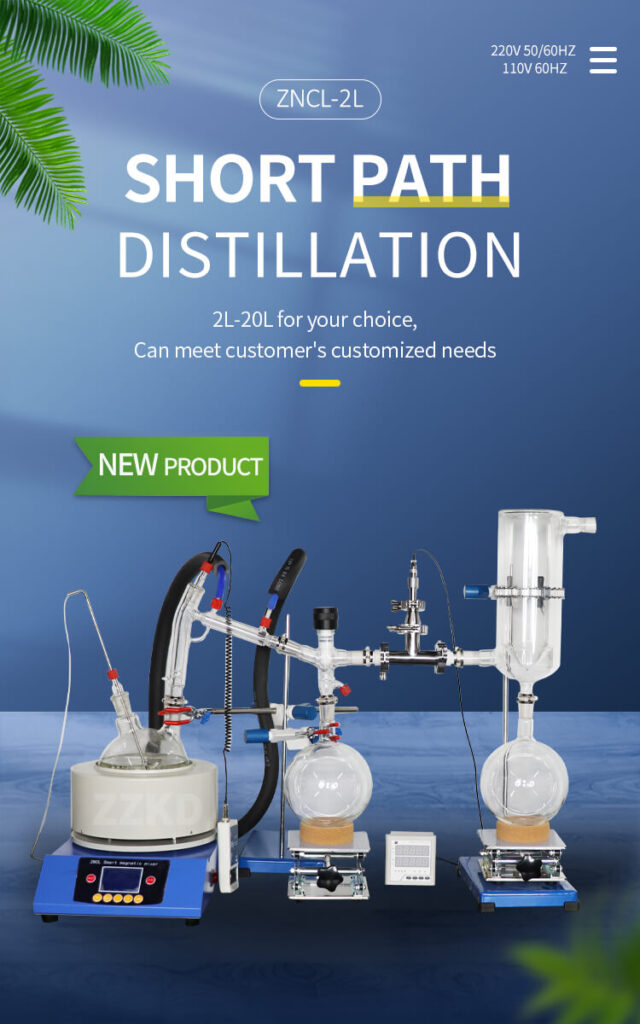

In the realm of laboratory equipment and scientific advancements, 20l short path distillation kit stands as a crucial technique, especially in fields like chemical and biological pharmaceuticals. Companies like ZZKD Machinery and Instrument Equipment Co., Ltd. have been at the forefront of developing and supplying distillation equipment for various applications. But how does short path distillation work, and why is it so essential? Let’s delve into the intricacies of this process.

The Basics of Short Path Distillation

Short path distillation stands as a crucial technique for purifying high-boiling compounds. By operating under reduced pressure, this method effectively lowers boiling points, preserving the integrity of compounds that are prone to degradation at higher temperatures. This process is especially valuable for handling complex mixtures such as oils and waxes.

Short path distillation involves heating the mixture in a flask, causing volatile components to evaporate. These vapors then travel a short distance to a condenser, where they rapidly cool and condense back into a liquid state. The resulting liquid is collected separately. This method’s ability to distill compounds at lower temperatures, combined with its efficiency in preventing thermal degradation, positions it as a cornerstone technique in various industries.

The Distillation Process: Step by Step

1. Evaporation: The process begins with the heating of the mixture in a flask. As the mixture heats up, the volatile components start evaporating. In short path distillation, the pressure is significantly reduced, allowing the compounds to vaporize at lower temperatures.

2. Separation: The vaporized compounds then travel a short distance to a condenser. The condenser cools the vapor rapidly, causing it to condense back into a liquid state. This condensed liquid is collected in a separate flask.

3. Fractional Distillation: The condensed liquid may contain a mixture of compounds with different boiling points. To further purify the components, multiple distillation steps can be employed, each time collecting fractions with distinct properties.

Advantages of Short Path Distillation

1. Gentle Processing: One of the primary advantages of short path distillation is its ability to operate at lower temperatures due to reduced pressure. This gentle process helps prevent thermal degradation and preserves the quality of the compounds.

2. High Purity: Short path distillation allows for the separation of compounds with high boiling points without the risk of cross-contamination or undesired chemical reactions, resulting in high-purity end products.

3. Efficiency: The short path between the evaporation flask and the condenser minimizes the loss of volatile compounds during the distillation process. This efficiency is crucial in industries where yield and purity are paramount.

Applications of Short Path Distillation

Short path distillation finds applications in various industries, including:

1. Pharmaceuticals: In the pharmaceutical industry, short path distillation is used to purify active pharmaceutical ingredients (APIs) and separate different components of complex mixtures.

2. Cannabis Extraction: Short path distillation is widely employed in the extraction of cannabinoids from cannabis plants. It allows for the isolation of compounds like CBD and THC with high purity.

3. Essential Oils: The production of essential oils often involves short path distillation to extract fragrant and therapeutic compounds from plants.

Innovations in Short Path Distillation

As industries push the boundaries of scientific exploration, short path distillation remains a stalwart technique, continuously benefiting from innovative advancements. These breakthroughs have redefined the landscape of laboratory equipment, making processes more efficient and outcomes more precise.

Precision Temperature Control: One notable innovation is the integration of precise temperature control systems. This allows researchers and manufacturers to maintain optimal conditions throughout the distillation process, resulting in higher yields and purer products.

Automated Systems: Automation has also transformed short path distillation. Modern systems can be programmed to follow specific protocols, reducing the need for manual intervention and minimizing human error. This level of automation streamlines workflows and enhances reproducibility.

Enhanced Vacuum Technology: Vacuum systems have undergone significant improvements, enabling better control over pressure conditions. This refinement optimizes the separation of compounds, particularly those with varying boiling points.

Real-time Monitoring: Innovations in sensor technology facilitate real-time monitoring of critical parameters such as temperature, pressure, and flow rates. This data-rich approach empowers operators to make informed decisions, ensuring consistent and high-quality results.

Integration of Data Analytics: The coupling of short path distillation setups with data analytics tools has revolutionized process optimization. By analyzing collected data, researchers can uncover insights that lead to further refinement and innovation.

In the dynamic world of scientific progress, these innovations exemplify the commitment of companies like ZZKD Machinery and Instrument Equipment Co., Ltd. to pushing the boundaries of possibility. As short path distillation continues to evolve, these advancements will undoubtedly shape the future of laboratory techniques and their impact on various industries.

Conclusion

Short path distillation, a cornerstone of modern laboratory equipment, plays a pivotal role in producing high-purity compounds in various industries. ZZKD Machinery and Instrument Equipment Co., Ltd. and similar companies have been instrumental in advancing this technique through their commitment to innovation and quality. Understanding how short path distillation works opens the door to harnessing its potential in research, manufacturing, and technological advancement.