Introduction to Continuous High Pressure Reactors

The realm of chemical research and industrial synthesis has been profoundly transformed by the advent of continuous high pressure reactors. These innovative systems offer an unparalleled ability to maintain consistent high pressures and temperatures, a feature pivotal in many chemical processes. The integration of continuous high pressure reactors into various fields, ranging from pharmaceuticals to material science, has not only enhanced efficiency but also opened new avenues for experimentation and discovery.

In this dynamic landscape, the continuous high pressure reactor emerges as a crucial tool, enabling scientists and industries to push the boundaries of chemical synthesis. Its significance lies in its ability to facilitate reactions that are otherwise challenging or impossible under normal conditions. This technological marvel has thus become a cornerstone in modern laboratories, redefining the possibilities in chemical and material research.

The Role of High Pressure in Chemical Synthesis

High pressure in chemical reactions is not just a condition but a catalyst that can dramatically alter reaction outcomes. It has the profound ability to influence reaction rates, improve yields, and even lead to the formation of new compounds that are unattainable under normal atmospheric conditions. The continuous high pressure reactor excels in providing this crucial element of high pressure, allowing for precise control over reaction parameters.

This precision in controlling pressure conditions unlocks a realm of chemical reactions previously deemed too complex or unfeasible. It enables researchers to delve into uncharted territories of chemical synthesis, exploring novel pathways and synthesizing compounds with unique and desirable properties. This aspect of high pressure plays an instrumental role in advancing research and development across various scientific disciplines.

Continuous Versus Batch Reactors: A Comparative Analysis

The shift from traditional batch reactors to continuous high pressure reactors marks a significant milestone in the evolution of chemical processing. Batch reactors, while useful, are often limited by their discontinuous nature, posing challenges in scalability and efficiency. Continuous reactors, on the other hand, operate without interruption, ensuring a steady flow of reactants and products. This continuous operation is a game-changer, especially in industrial synthesis, where consistency, efficiency, and volume of output are paramount.

By maintaining reaction conditions steadily, continuous high pressure reactors minimize the risk of inconsistencies and enhance the overall quality of the end products. They represent a more sustainable and economical choice, reducing waste and energy consumption. This continuous approach is not just a technological upgrade but a paradigm shift in how chemical processes are conceptualized and executed.

Lab Scale High Pressure Reactors: A Necessity for Research and Development

Lab scale high pressure reactors play a crucial intermediary role in bridging the gap between experimental research and industrial application. These reactors, designed for laboratory settings, are essential for the development, testing, and optimization of processes under high-pressure conditions before they are scaled up for industrial use.

These lab-scale units provide researchers with a controlled environment to safely experiment with reactions that require high pressure. They are instrumental in fine-tuning reaction conditions, studying reaction kinetics, and understanding the effects of pressure on various chemical processes. This step is vital in ensuring that once a process is scaled up to an industrial level, it is efficient, safe, and economically viable.

The Evolution of Reactor Design and Emphasis on Safety

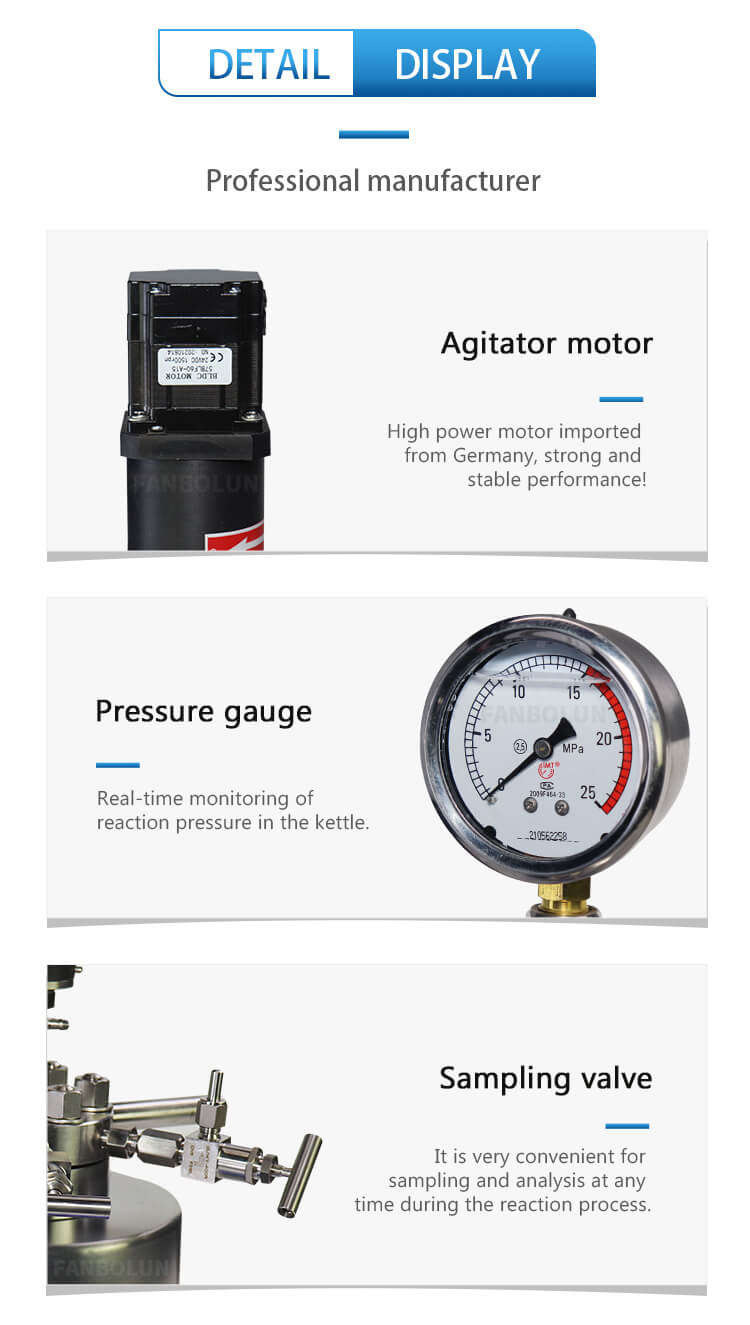

The design of continuous high pressure reactors has seen significant advancements over the years, with an increasing focus on safety, durability, and user-friendliness. Modern reactors are constructed with high-quality materials capable of withstanding extreme conditions, ensuring long-term durability and reliability.

Safety features in these reactors have become more sophisticated, with advanced pressure relief systems and fail-safes to prevent accidents. The user interface and control systems are designed to be intuitive, allowing precise control over reaction conditions with ease. These design improvements not only enhance the safety of the reactors but also ensure consistent and reliable performance, which is crucial in both research and industrial settings.

Diverse Applications in Pharmaceutical and Material Science

The application of continuous high pressure reactors spans across various fields, with notable impacts in pharmaceuticals and material sciences. In the pharmaceutical industry, these reactors are essential for synthesizing complex organic molecules, often leading to the development of new drugs and treatments. The precise control over reaction conditions allows for the creation of purer compounds and enhances the efficiency of the synthesis process.

In material science, continuous high pressure reactors are instrumental in developing new materials like advanced polymers, composites, and nanomaterials. The ability to maintain high pressures and temperatures enables the formation of materials with unique properties and enhanced performance. These materials find applications in various industries, ranging from aerospace to consumer products, underscoring the versatility and importance of high-pressure reactors in material development.

FBL Machinery: Pioneering in High Pressure Reactor Technology

FBL Machinery and Instrument Equipment Co., Ltd. stands as a leader in the field of high-pressure reactor technology. With over 13 years of expertise in research, development, and manufacturing of high-quality continuous high pressure reactors, FBL has established itself as a trusted partner for industries and research institutions worldwide.

Their commitment to innovation and quality, coupled with a global presence and comprehensive customer support, makes FBL an ideal choice for those seeking advanced reactor solutions. Their reactors are not only designed to meet the highest international safety standards but are also tailored to meet specific customer needs, ensuring optimal performance and reliability.

Conclusion: Embracing the Future with Continuous High Pressure Reactors

The continuous high pressure reactor represents a significant leap forward in the field of chemical synthesis and material science. Its ability to maintain controlled high-pressure conditions continuously has revolutionized research and industrial processes. For laboratories and industries aiming to leverage the advantages of these advanced systems, FBL Machinery and Instrument Equipment Co., Ltd. offers the expertise and technology to make it a reality.

Explore the possibilities and transform your chemical processes with FBL’s state-of-the-art continuous high pressure reactors. Visit FBL’s website to discover more about their products and services, and take the first step towards a more efficient and innovative future in chemical processing.