In the ever-evolving landscape of scientific research and technological innovation, the high pressure hydro autoclave reactor stands out as a pivotal development. Particularly in the realm of chemical engineering and materials science, this advanced system, including its lab scale high pressure reactor variant, is revolutionizing how we approach synthesis and experimentation under extreme conditions.

The Essence of High Pressure Hydro Autoclave Reactors

At its core, the high pressure hydro autoclave reactor is designed to operate under significantly elevated pressures and temperatures. This capability is crucial in simulating environments that are otherwise challenging to replicate in a standard laboratory setting. The reactor typically consists of a robust, sealed chamber that can withstand the rigors of high pressure, ensuring safety and reliability during experiments.

The versatility of these reactors is evident in their wide range of applications. From hydrothermal synthesis to the study of supercritical fluids, these reactors provide an invaluable tool for researchers. The controlled environment allows for precise manipulation of variables, leading to more accurate and reproducible results.

Advancements in Design and Materials

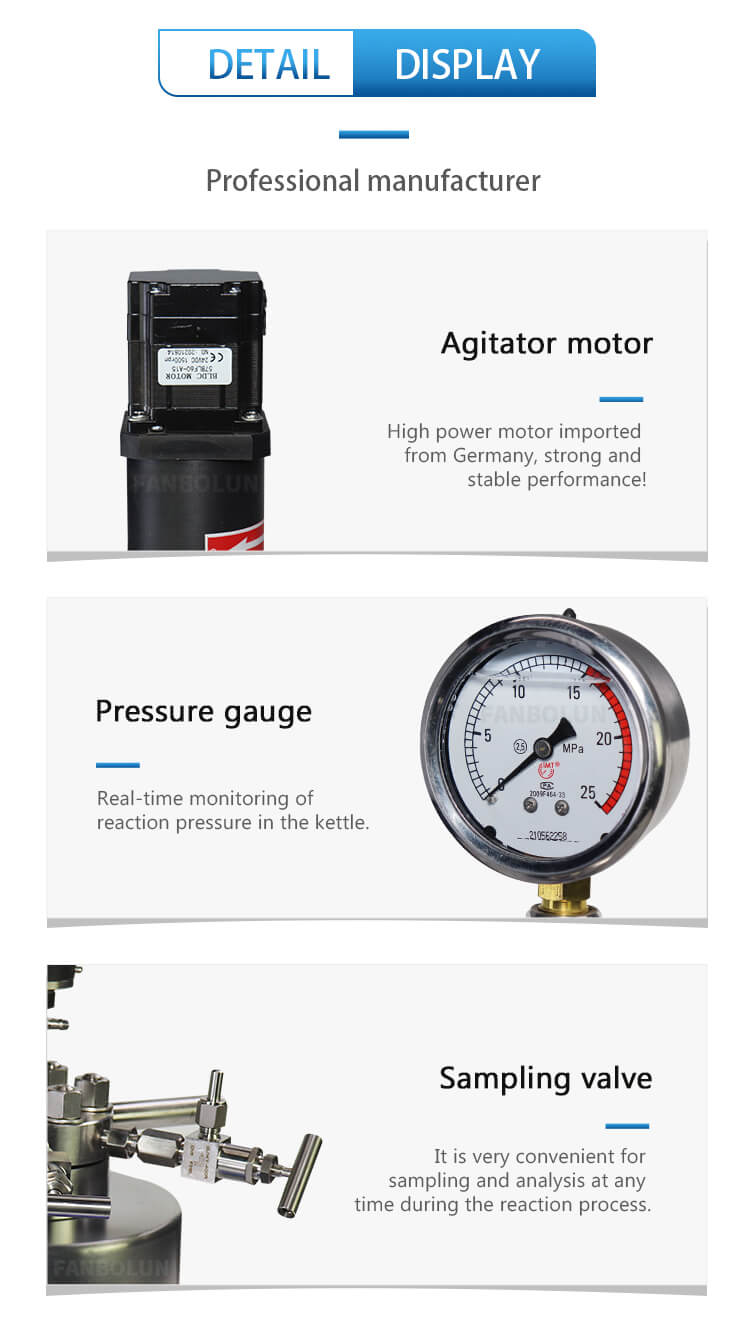

Recent advancements in the design of high pressure hydro autoclave reactors have been remarkable. Modern reactors are now equipped with state-of-the-art safety features, including pressure relief systems and robust locking mechanisms. These enhancements not only improve the safety of the reactors but also increase their operational lifespan.

Material innovation has also played a significant role. The use of high-strength alloys and composites in constructing the reactor chamber ensures that it can withstand the extreme conditions without compromising its structural integrity. This development has expanded the range of experiments that can be safely conducted within these reactors.

Lab Scale High Pressure Reactors: A Closer Look

Lab scale high pressure reactors, a subset of the high pressure hydro autoclave reactor family, are particularly noteworthy. These compact units are ideal for smaller-scale experiments, offering the same capabilities as their larger counterparts but in a more manageable size. This makes them perfect for academic and small-scale industrial research where space and resources might be limited.

Despite their smaller size, these lab scale reactors do not compromise on functionality. They are equipped with advanced control systems that allow for precise regulation of temperature and pressure, essential for conducting sensitive experiments that require meticulous parameter control.

Application in Chemical Synthesis

One of the primary applications of the high pressure hydro autoclave reactor is in the field of chemical synthesis. Under high pressure and temperature conditions, chemical reactions can proceed at a much faster rate and often with greater selectivity. This efficiency is particularly beneficial in synthesizing complex molecules, such as pharmaceuticals and polymers.

Moreover, these reactors enable the exploration of novel reaction pathways that are not feasible under normal conditions. This aspect opens up new possibilities in synthetic chemistry, potentially leading to the discovery of new compounds and materials.

Environmental Impact and Green Chemistry

The high pressure hydro autoclave reactor also plays a significant role in environmental research and green chemistry. By facilitating reactions under high pressure, it’s possible to reduce the need for hazardous solvents, thus minimizing waste and environmental impact. This aligns with the principles of green chemistry, which aim to make chemical production more sustainable.

Additionally, these reactors can be used to study and optimize processes like carbon capture and storage, a critical aspect of combating climate change. By understanding how different compounds behave under high pressure, scientists can develop more efficient methods for capturing greenhouse gases.

Future Prospects and Innovations

Looking ahead, the potential for innovation in high pressure hydro autoclave reactor technology is vast. One area of focus is the integration of advanced sensors and automation to enhance the precision and efficiency of experiments. By incorporating real-time monitoring and control, researchers can achieve a new level of accuracy in their work.

Another exciting prospect is the development of even more resilient materials for reactor construction, which could enable experimentation at even higher pressures and temperatures. This advancement could unlock new scientific frontiers, particularly in the study of extreme conditions similar to those found in deep-sea vents or other planets.

Conclusion

The high pressure hydro autoclave reactor, including its lab scale variants, represents a significant leap forward in scientific and technological capabilities. Its impact spans multiple disciplines, from chemistry to environmental science, and its potential for future advancements is boundless. As we continue to explore the capabilities of these remarkable tools, we can expect a wealth of new discoveries and innovations that will shape the future of science and technology.