Introduction To High Pressure Reactor System

In High Pressure Stirred Reactor under the ultra-high pressure and high temperature conditions, the raw materials are continuously dissolved under the action of a strong alkaline solvent, and then continue to crystallize around the seed crystal soaked in the dissolved solution, thereby forming a very pure and transparent artificial crystal. The main sealing port of the high pressure reactor system adopts double-line sealing, and the other sealing points adopt the sealing form of the line contact between the arc surface and the plane, and between the arc surface and the arc surface. Relying on the high precision and smoothness of the contact surface, it can achieve Good sealing effect.

Composition Of High Pressure Reactor System

The high pressure reactor system is composed of agitator, reaction vessel and transmission system, safety device, cooling device, heating furnace and other parts.

1. The kettle body and the kettle cover are made of specific stainless steel. The kettle body is connected with the thread through the flange, and the kettle cover is a flat flat cover. These two parts are tightened by circumferentially distributed nuts and main bolts fixed connection.

2. The main sealing port of the high pressure reactor system is double-line sealed, and the rest of the sealing points generally adopt the sealing form of the line contact between the plane and the arc surface, and the arc surface and the arc surface, relying on the contact surface The ultra-high precision and finish achieve a very good sealing effect.

3. A barrel-shaped silicon carbide furnace core is installed outside the kettle body, and the electric furnace wire passes through the furnace core, and its end passes through the lower part of the furnace shell side, and is connected to the controller through a connecting stud and a rubber-sheathed cable.

4. The coupling is mainly composed of a pair of inner and outer magnetic rings with strong magnetic force, and there is a pressure-bearing spacer in the middle. The stirrer is driven by a servo motor through a coupling. The purpose of controlling the stirring speed can be achieved by controlling the speed of the servo motor.

5. A tachometer coil is installed on the upper part of the spacer. When the integrated stirrer and the inner magnetic ring rotate, the tachometer coil will generate an induced electromotive force, which corresponds to the stirring speed. Rotating speed.

6. The lid of the kettle is equipped with a pressure gauge, a bursting membrane safety device, a vapor-liquid phase valve, a temperature sensor, etc., so that it is convenient to know the reaction situation in the kettle at any time, adjust the medium ratio in the kettle, and ensure the safe operation of the high pressure reactor system.

7. The bearing adopts stainless steel bearing or high-strength electrochemical graphite, which is wear-resistant and has a long maintenance cycle.

8. There is a cooling water jacket between the magnetic coupling and the lid of the kettle. When the operating temperature is high, the cooling water should be passed through, and the temperature of the magnetic steel is too high to cause demagnetization.

Features Of High Pressure Reactor System

1. The lid of the high pressure reactor system is equipped with a pressure gauge, a bursting membrane safety device, a vapor-liquid phase valve, a temperature sensor, etc., so that it is convenient to know the reaction situation in the kettle at any time, adjust the medium ratio in the kettle, and ensure safe operation.

2. A cooling water jacket is installed between the high pressure reactor system coupling and the lid of the kettle. When the operating temperature is high, the cooling water should be passed through, and the magnetic steel temperature is too high to cause demagnetization.

3. The kettle body and lid of the high pressure reactor system are made of 1Cr 18Ni 9Ti stainless steel. The kettle body is connected to the flange through threads, and the kettle lid is a flat plate lid. The two are fastened and connected by the main bolts and nuts uniformly distributed in the circumferential direction.

4. The main sealing port of the high pressure reactor system adopts A-type double-line sealing, and the other sealing points adopt the sealing form of the line contact between the arc surface and the plane, and the arc surface and the arc surface, relying on the high precision and smoothness of the contact surface , to achieve a good sealing effect.

5. The body of the high pressure reactor system is equipped with a barrel-shaped silicon carbide furnace core, and the electric furnace wire passes through the furnace core, and its end passes through the lower part of the furnace shell side, and is connected to the controller through a connecting stud and a rubber-sheathed cable.

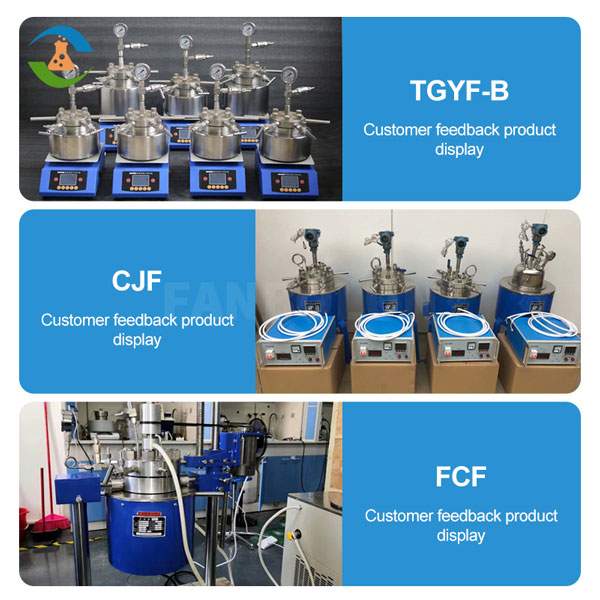

Application Of High Pressure Reactor System

The high pressure reactor system is widely used in the laboratory, especially the miniature high pressure reactor system. The hot-selling models include miniature high pressure reactor systems ranging from 10ML to 500ML. The material is divided into stainless steel miniature high pressure reactor system, Hastelloy miniature stainless steel reactor, titanium miniature high pressure reactor system. Magnetic stirring is widely used. Of course, mechanical stirring can also be added in a certain size. It is also called double-stirring miniature high pressure reactor system, including some that need to add a light source. It can be made into a miniature visible high pressure reactor system and a miniature hydrogenation high pressure reactor system. wait.

High pressure reactor system is widely used in petroleum, chemical industry, rubber, pesticide, dyestuff, medicine, food, pressure vessel used to complete vulcanization, nitration, hydrogenation, alkylation, polymerization, condensation and other processes, such as reactor, reactor, Decomposition pot, polymerization pot, etc.; materials generally include carbon-manganese steel, stainless steel, zirconium, nickel-based (Hastelloy, Monel, Inconel) alloys and other composite materials.

Frequently Questions About High Pressure Reactor System

The high pressure reactor system is a common chemical reaction equipment in the laboratory. It is inevitable to encounter some failures during the experiment. How should we troubleshoot it?

1. There is leakage at the sealing surface of the kettle lid and the kettle body.

It is very likely that the nut thread of the micro high pressure reactor system is loose; the sealing surface is damaged.

The method of exclusion is to re-tighten the nut; repair and polish the sealing surface.

2. Leakage occurs at the valve and each joint.

The reason for the analysis is that the micro high pressure reactor system valve needle and the sealing surface of the valve port are damaged, and the joint is loose.

The way to get rid of it is to grind the valve needle, valve port or replace the valve; tighten the joint clockwise.

3. The motor rotates, but the magnet does not rotate, and the current of the motor decreases.

The reason for the analysis is that the temperature in the micro high pressure reactor system is too high, and there is a problem with the cooling system, and the magneton is demagnetized due to high temperature.

The way to get rid of it is to notify the supplier and replace it with a new one.

4. There is friction noise when stirring.

The reason for the analysis is that the magnetic steel on the motor has attracted foreign matter.

The way to get rid of it is to open the case and clean up the foreign matter.

5. The power on indicator light is off.

The analysis reasons are: the indicator light is broken or not tightened, the fuse is blown, and the switch is in poor contact.

Remedy: Check the light bulb, the voltmeter measures around 6V, check for short circuits, and switch.

6. The motor of the speed control button does not turn.

The reasons for the analysis are: the SCR is broken, the motor is damaged, the wiring is wrong, and the fuse is blown.

Remedy: adjust the thyristor, adjust the motor, and connect according to the circuit diagram.