The Role of Multi-Purpose Glass Reactors

Multi-purpose glass reactors are indispensable tools in various industries, including chemical synthesis, pharmaceutical research, and production. These versatile equipment facilitate controlled reactions by providing a transparent and inert environment. The glass construction allows for excellent visibility and monitoring of processes, ensuring precision and safety. Multi-purpose 10l reactor offer several advantages over traditional reactors, including corrosion resistance, thermal stability, and the ability to incorporate additional features for enhanced functionality.

Key Features and Benefits of Multi-Purpose Glass Reactors

Multi-purpose glass reactors possess key features that enhance their efficiency and versatility in various applications. These features include robust construction for durability, precise control systems for accurate parameter adjustments, safety measures for operator protection, and easy maintenance for seamless operation. By investing in high-quality multi-purpose glass reactors, buyers can benefit from improved yield, enhanced product purity, and streamlined processes. Additionally, the transparent nature of glass reactors allows for real-time observation and adjustments, ensuring optimal reaction conditions. Now, let’s delve deeper into the various aspects of multi-purpose glass reactors to aid buyers in their purchasing decisions.

Types of Multi-Purpose Glass Reactors

Single-layer glass reactors

Single-layer glass reactors consist of a single glass container or vessel for the reaction, and generally rely on external heating or cooling to control the reaction temperature. This may involve regulating the temperature of the reaction vessel using a heating mantle, heating bath, or cooling bath. In single-layer glass reactors, heat transfer occurs primarily through direct contact between the reaction mixture and the heating or cooling source. This can lead to slower and less efficient heat transfer, affecting reaction kinetics and the ability to achieve precise temperature control.

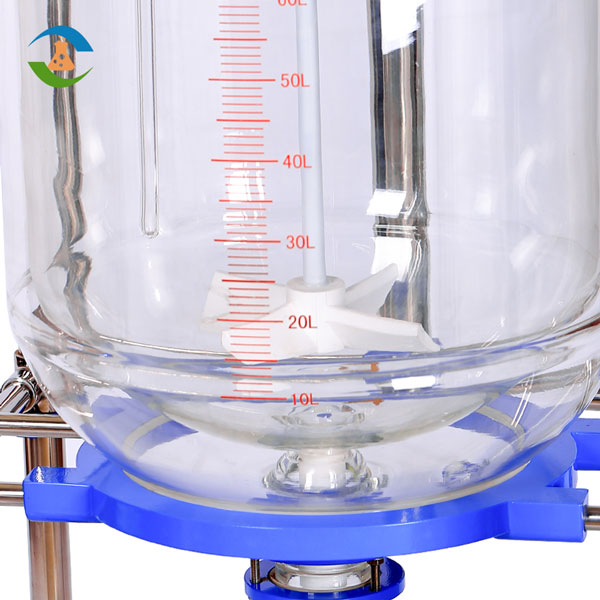

Double-layer glass reactor

Double-layer glass reactor, also known as a jacketed glass reactor, consists of two glass vessels. The inner vessel holds the reaction mixture, while the outer vessel acts as a temperature-controlled jacket. The space between the inner and outer containers is filled with a circulating fluid, such as oil or water, to provide efficient heating or cooling. Double glass reactors provide better temperature control due to the presence of the jacket. The jacket enables precise and efficient heating or cooling of the reaction mixture. By circulating a temperature-controlled fluid in the jacket, the reaction temperature can be accurately maintained, enhancing experimental control and reproducibility.

Advantages of Multi-Purpose Glass Reactors

Multi-purpose glass reactors provide numerous advantages for scientific research and industrial applications. These advantages include:

Transparency: The glass construction allows for clear visibility of reactions, facilitating real-time monitoring and adjustments.

Corrosion Resistance: Glass reactors, particularly those made of borosilicate glass, exhibit excellent resistance to corrosion from various chemicals, ensuring their durability and longevity.

Thermal Stability: Glass reactors can withstand a wide range of temperatures, allowing for reactions that require both low and high temperatures.

Versatility: Multi-purpose glass reactors can be equipped with additional features such as reflux condensers, distillation setups, and variable speed agitators, expanding their functionality for different applications.

Compatibility: Glass reactors are compatible with a wide range of chemicals, solvents, and reagents, making them suitable for various reaction types and processes.

When Buying Multi-Purpose Glass Reactors

Capacity and Volume

When purchasing a multi-purpose glass reactor, it is essential to determine the appropriate capacity and volume required for your specific applications. Consider the scale of your experiments or production processes to ensure that the reactor can accommodate the desired quantities of reactants and products.

Temperature and Pressure Range

Different reactions require specific temperature and pressure conditions. Therefore, it is crucial to choose a glass reactor that offers a wide range of temperature and pressure control capabilities to meet the requirements of your applications. This ensures that the reactor can accommodate both low-temperature reactions and high-temperature processes, providing flexibility for a range of experiments.

Material Compatibility

Another important factor to consider is the material compatibility of the reactor. Ensure that the materials of construction are compatible with the chemicals and solvents used in your processes. Opt for high-quality borosilicate glass reactors that offer excellent resistance to chemical corrosion and thermal shock, ensuring long-term reliability and safety.

Mixing and Stirring Mechanisms

Efficient mixing is essential for achieving uniform distribution of reactants and enhancing reaction kinetics. When selecting a multi-purpose glass reactor, consider the mixing and stirring mechanisms available. Look for reactors equipped with variable speed agitators or magnetic stirrers, which enable efficient mixing and ensure thorough blending of reactants.

Price of a set of buy multi purpose glass reactors

The price of a glass reactor can vary greatly depending on several factors such as its capacity, functionality, and quality. In general, smaller glass reactors with lower capacity and less advanced features tend to be less expensive than larger reactors with higher capacity and advanced features.

As a rough guide, a small glass reactor with a capacity of 1-5 liters can range from $500 to $5,000, depending on quality and additional features. Mid-range glass reactors with a capacity of 5-20 liters typically cost $5,000 to $15,000.

For large glass reactors with capacities greater than 20 liters, prices can range from $15,000 to $50,000 or more, depending on specific requirements and custom options.

It is important to note that these price ranges are approximate and may vary based on various factors such as geographic location and other accessories or features included with the glass reactor.

When considering price, it is critical to balance your budget with the specifications and features you need to ensure that the glass reactor you invest in is reliable and suitable for your specific needs. For details you can contact us.

FBL Hot sale

Small multi purpose glass reactors

- Model:S-2L

- Power(W ):60

- StirringSpeed(rmp):0~600(Max.1300)

- Diameter:12

- Capacity(L):2

- Power Supply:220V 50/60 Hz

- Motor Torque(g/cm):2400

Pilot multi purpose glass reactors

- Model:S-50L

- Power(W ):120

- StirringSpeed(rmp):0~600(Max.1300)

- Diameter:12

- Capacity(L):50

- Power Supply:220V 50/60 Hz

- Motor Torque(g/cm):1500

Large multi purpose glass reactors

- Model:S-100L

- Power(W ):250

- StirringSpeed(rmp):0~600(Max.1300)

- Diameter:15

- Capacity(L):100

- Power Supply:220V 50/60 Hz

- Motor Torque(g/cm):3000