Distillation is a fundamental separation technique used in various industries to extract and purify components from liquid mixtures. One such distillation method is short path distillation, known for its efficiency and versatility in separating volatile compounds. In this article, we will delve into the world of short path distillation, with a specific focus on the 1L short path distillation kit. Additionally, we will explore an application case that highlights the practical uses and benefits of this compact distillation setup.

Understanding Short Path Distillation:

2L Short Path Distillation Kit is a technique that utilizes differences in boiling points to separate volatile components from a liquid mixture. It involves heating the mixture in a flask while the vapor rises and travels through a short path condenser. The condenser efficiently cools the vapor, causing it to condense and collect as a separate fraction. This process is particularly effective for separating compounds with close boiling points or those that are thermally sensitive.

The 1L Short Path Distillation Kit:

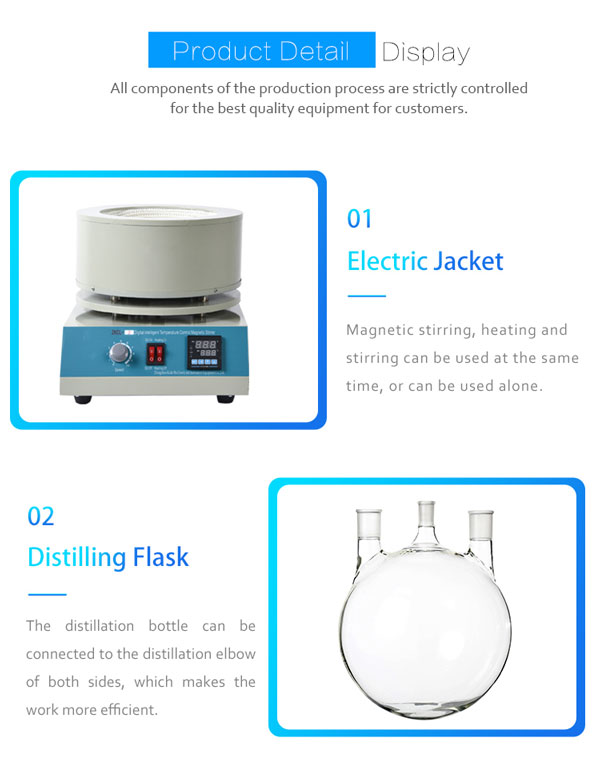

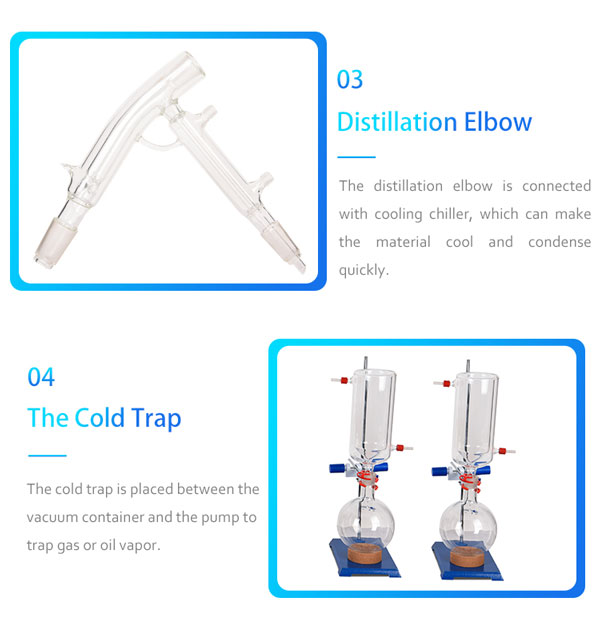

The 1L short path distillation kit is a compact and versatile setup designed for small-scale distillation processes. It typically includes a heating mantle, a round-bottom flask, a short path condenser, a vacuum pump, and a collection flask. The kit’s compact size makes it ideal for laboratories, research facilities, and production settings where space may be limited. Despite its small volume capacity, the 1L kit maintains high efficiency and precision, ensuring reliable results.

Features and Benefits:

The 1L short path distillation kit offers several features and benefits that contribute to its popularity among researchers and professionals in various industries. Let’s explore some of its key advantages:

a. Space-Efficient Design:

The compact size of the 1L kit allows for easy installation in crowded laboratory spaces. It is an excellent choice for small-scale operations, providing efficient distillation within a limited footprint.

b. Enhanced Heat Transfer:

The short path condenser’s design ensures optimal heat transfer, promoting efficient cooling and condensation of the vapor. This feature contributes to the kit’s ability to handle a wide range of compounds effectively.

c. Precise Temperature Control:

The heating mantle in the 1L kit enables accurate and precise temperature control during distillation. This control is essential when separating compounds with close boiling points or when working with heat-sensitive materials.

d. Rapid Distillation:

Due to the shorter path length and efficient condensation, the 1L short path distillation kit allows for faster distillation cycles compared to traditional distillation setups. This feature enhances productivity and reduces processing time.

e. High Purity Results:

The efficient separation capabilities of the 1L kit result in high purity fractions. This makes it an invaluable tool for purifying chemicals, extracting essential oils, producing pharmaceutical intermediates, and obtaining high-quality distillates.

Short Path Distillation Kit VS Traditional Distillation Setup:

a. Efficiency: Short path distillation offers higher efficiency due to the shorter path length and efficient condensation. This leads to faster distillation cycles and increased productivity compared to traditional distillation setups.

b. Precision: Short path distillation kits typically have precise temperature control, allowing for accurate separation of compounds with close boiling points or heat-sensitive materials.

c. Space Efficiency: Short path distillation kits, especially the smaller ones like the 1L kit, require less space compared to traditional setups. This makes them suitable for laboratories and research facilities with limited space.

Short Path Distillation Kit VS Fractional Distillation Equipment:

a. Simplicity: Short path distillation kits are generally easier to set up and operate compared to fractional distillation equipment. They often come as complete kits with all necessary components, making them user-friendly and accessible.

b. Flexibility: Short path distillation kits offer versatility in handling a wide range of compounds, including those with close boiling points or thermal sensitivity. Fractional distillation may have limitations when it comes to separating such compounds effectively.

c. Scale: Short path distillation kits are available in various sizes, including smaller options like the 1L kit. This scalability allows users to choose the appropriate kit size based on their specific needs, whether for small-scale research or larger production processes.

Short Path Distillation Kit VS Vacuum Distillation Apparatus:

a. Purity: Short path distillation kits excel in producing high-purity distillates. The efficient separation capabilities and precise temperature control minimize impurities, making them suitable for applications that require purified compounds.

b. Speed: Short path distillation kits generally offer faster distillation cycles compared to vacuum distillation apparatus. This can be attributed to the efficient condensation and shorter path length, allowing for quicker separation and collection of fractions.

c. Ease of Operation: Short path distillation kits are often designed with user-friendliness in mind. They typically come with clear instructions and are easier to set up and operate compared to complex vacuum distillation apparatus.

In summary, short path distillation kits offer several advantages over traditional distillation setups, fractional distillation equipment, and vacuum distillation apparatus. They are known for their efficiency, precision, space efficiency, simplicity, versatility, scalability, and ability to produce high-purity distillates. These advantages make short path distillation kits an attractive choice for various applications in industries such as chemistry, pharmaceuticals, essential oil extraction, and more.