In the pursuit of sustainability and environmental responsibility, industries are continuously seeking innovative solutions to reduce waste and minimize their ecological footprint. One such groundbreaking technology is the paint solvent recycling machine. This state-of-the-art device revolutionizes the management of acetone waste, offering an efficient and cost-effective means of recycling this volatile organic compound. By recovering and purifying used acetone, the Acetone Recycler not only mitigates environmental pollution but also provides economic benefits and enhances operational efficiency for industries across various sectors.

Understanding the acetone recycler

The Acetone Recycling Machine is a sophisticated device designed to collect, filter, purify, and recover acetone from industrial waste streams. This cutting-edge technology represents a significant step forward in sustainable practices, allowing industries to minimize their reliance on new acetone production and reduce the amount of hazardous waste generated.

The machine’s core components work seamlessly together to achieve optimal recycling results:

Collection System:

The Acetone Recycling Machine is equipped with a robust collection system that efficiently captures waste acetone from industrial processes. This can include acetone used as a solvent in manufacturing, cleaning, or other applications.

Filtration and Purification:

Once collected, the waste acetone undergoes a series of filtration and purification stages. Advanced techniques such as distillation, membrane separation, or adsorption are employed to remove impurities, contaminants, and unwanted substances. These processes ensure that the recycled acetone meets the required quality standards for reuse.

Condensation and Recovery:

The purified acetone vapor is carefully condensed back into a liquid form, facilitating its efficient recovery. This step maximizes acetone recovery rates while minimizing losses, ensuring a high yield of reusable acetone.

Quality Control:

To guarantee the recycled acetone’s quality and suitability for reuse, rigorous quality control measures are implemented. Comprehensive testing and analysis verify the purity, composition, and other essential parameters, ensuring compliance with industry standards.

Reintegration into Industrial Processes:

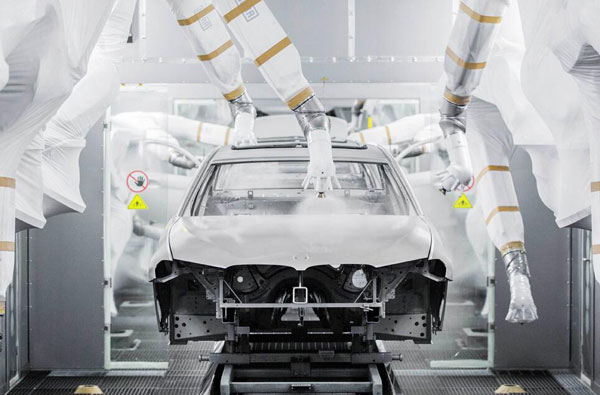

Once the recycled acetone meets the necessary quality criteria, it is ready for reintroduction into industrial processes. Manufacturers can seamlessly incorporate the recycled acetone into various applications that require acetone as a solvent or component, such as in paint, coatings, adhesives, or pharmaceutical production.

Acetone recycler features:

-Cooling adopts Taiwan accessories, and the recovery rate is increased by 80%;

-The double-station machine turns over the material, and the operation is safer;

-Japan Omron intelligent temperature control to solve the foaming problem;

-Configure timing shutdown to avoid gas explosion;

-High boiling point solvent, equipped with a vacuum pump;

-Rectangular bracket is used, which is firm and stable without tilting;

-American original diaphragm pump and Calstar vacuum pump, remote delivery of solvents.

-Japan original circulating heat medium oil pump, more uniform heating, 50% faster recovery speed;

-Italian original hydraulic scraper power; complete slag removal within 1 minute;

-Explosion-proof automatic feeding system; more labor-saving;

-Lower the slag discharge system and complete the slag discharge within 30 seconds.

Application of paint acetone recycler:

Electronic product manufacturing (such as: lcd, led, etc.):

Cleaning agents used to clean molds and clean electronic products themselves, such as absolute ethanol, acetone, trichlorethylene, etc.

Manufacturing of precision instruments and hardware products:

Organic solvents for cleaning molds and processed products, such as thinners, hydrocarbons, kerosene, solvent gasoline, etc.

Sports Equipment Manufacturing:

Cleaning agent for melting wax castings such as golf heads and fishing rods, as well as solvent for spraying and cleaning clubs and fishing rods.

FRP products industry:

Solvents for surface protection and aesthetic coating production processes, e.g. yacht production, wind turbine blade production, etc.

Painted gold jewelry industry:

Solvent for surface pretreatment cleaning and pre-plating treatment.

Optical products:

Solvents used in parts cleaning and pre-painting treatment in each production process.

Furniture manufacturing industry:

Organic solvents for cleaning spraying equipment and letdowns, such as thinners, xylene, methyl ethyl ketone, acetone, etc.

Why choose FBL acetone recycler

We can solve problems that other paint solvent recovery systems cannot

-The cooling system adopts air cooling to dissipate heat;

-Dumping function, convenient to clean up the residue after recycling;

-Unique segmental recovery function to solve the foaming problem of mixed solvents;

-Equipped with a corresponding Calstar condenser, which can recover low boiling point solvents from -25°C to 60°C;

-Equipped with corresponding Calstar vacuum pump, it can recover high boiling point solvent below 300℃;

-Using four-point support, the equipment is stable and safe.

Influential brand of FBL acetone recycler

(1). Obtained the product safety certification of the National Electrical Safety and Explosion Prevention Center: the product structure design and product manufacturing have been certified by authoritative organizations. The explosion-proof safety design of the whole machine and equipment components meets the national safety standards for explosion-proof electrical products, allowing you to use it worry-free and safe.

(2). The machine has excellent quality and stable performance: independent research and development, standardized mass production, and guaranteed quality.

(3). The machine has a wide range of applications: it can recycle common organic solvents in various industries.

(4). The recycling process is simple and the machine is easy to operate: ordinary employees can work safely after short-term training.

(5). Ultra-low machine maintenance cost: stable machine performance, durable, easy maintenance, less consumables.

(6). The recovered solvent is of good quality: the recovered solvent has positive color, clarification, purity and good performance.