In today’s rapidly evolving world, businesses are increasingly focusing on environmental sustainability, cost efficiency, and resource optimization. One area that has seen significant progress in achieving these goals is the recycling and reclamation of solvents. The emergence of Paint Solvent Recovery System has revolutionized how companies approach solvent management, offering a multitude of benefits and opportunities.

Enhancing Environmental Sustainability

Environmental sustainability has become a fundamental aspect of modern business practices. The use of solvents in various industrial processes often leads to their disposal as hazardous waste, posing risks to the environment and incurring substantial costs for businesses. However, the introduction of Solvent Recycling Units addresses these concerns by effectively reclaiming and recycling solvents that would otherwise be discarded. By recycling solvents, companies can significantly reduce their environmental impact, conserve natural resources, and minimize pollution. This approach aligns with global sustainability goals and allows businesses to demonstrate their commitment to environmental stewardship.

Cost Efficiency and Resource Optimization

The financial implications of solvent disposal can be substantial for businesses, with the costs of purchasing new solvents and disposing of hazardous waste adding up quickly. This is where Solvent Recycling Units provide a cost-effective solution. By enabling on-site solvent reclamation, these units minimize expenses associated with purchasing new solvents and disposing of hazardous waste. This leads to significant cost savings and optimized resource utilization, contributing to a more sustainable and profitable bottom line. Additionally, by reusing reclaimed solvents, businesses reduce their dependence on virgin materials, further reducing costs and environmental impact.

Versatile Applications across Industries

One of the remarkable aspects of Solvent Recycling Units is their versatility, catering to the diverse needs of various industries. Let’s explore some key sectors that have witnessed significant benefits from adopting this groundbreaking technology:

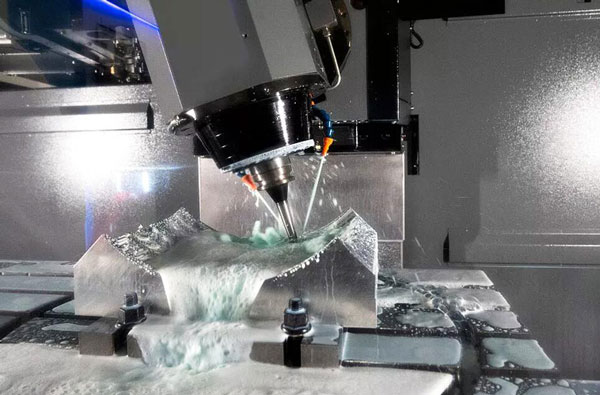

Manufacturing and Engineering:

Solvents play a vital role in manufacturing and engineering processes, such as cleaning parts and preparing surfaces. With Solvent Recycling Units, manufacturers can reclaim solvents, reducing their reliance on new materials and streamlining production efficiency. By reusing solvents, companies can achieve cost savings while minimizing their environmental footprint.

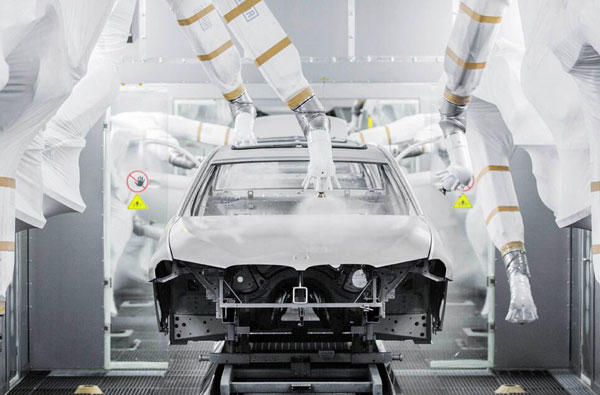

Automotive and Aerospace:

The automotive and aerospace industries often employ solvents for degreasing and cleaning delicate parts. Solvent Recycling Units enable these sectors to recover solvents effectively, ensuring compliance with stringent quality standards while reducing disposal costs. Reclaimed solvents can be reused, promoting sustainability and reducing the reliance on new solvent purchases.

Pharmaceuticals and Laboratories:

Laboratories and pharmaceutical companies utilize a wide range of solvents in their research, analysis, and production activities. The implementation of Solvent Recycling Units allows for the recovery and reuse of solvents, resulting in cost savings and a more sustainable approach to solvent management. By recycling solvents on-site, these industries can optimize their resources and contribute to a greener future.

Printing and Packaging:

Solvents are essential in the printing and packaging industry. With Solvent Recycling Units, printers can recycle and reuse solvents, reducing waste generation and the costs associated with purchasing new solvents. This not only benefits the environment but also improves the profitability and competitiveness of printing businesses.

Paint and Coating:

The paint and coating industries heavily rely on solvents for application and cleanup. By implementing Solvent Recycling Units, companies can reclaim solvents and reuse them, resulting in significant cost reductions and a more environmentally friendly approach to production. Reclaimed solvents can maintain high-quality standards, ensuring optimal performance in paint and coating applications.

Enhanced Occupational Health and Safety

Traditional methods of solvent disposal can pose risks to worker safety and the environment. The use of Solvent Recycling Units mitigates these hazards by eliminating the need for hazardous waste transportation and storage. On-site solvent recycling ensures the well-being of employees by reducing exposure to harmful chemicals and minimizing the risks associated with solvent disposal. Additionally, it enables companies to comply with stringent occupational health and safety regulations, providing a safe and healthy work environment.

Improved Process Efficiency and Time Savings

Implementing Solvent Recycling Units can streamline operations and enhance process efficiency. By recycling solvents on-site, businesses eliminate the delays associated with purchasing and transporting new solvents. This leads to significant time savings, allowing companies to focus on their core operations and meet project deadlines more effectively. Additionally, on-site solvent recycling eliminates the need to wait for solvent deliveries, ensuring a continuous supply and uninterrupted workflow.

Future Potential and Technological Advancements

Solvent Recycling Units are a technology that continues to evolve with advancements in the field. Researchers and engineers are constantly working towards improving efficiency, expanding the range of recyclable solvents, and reducing energy consumption. As the technology matures, Solvent Recycling Units have the potential to become an integral part of sustainable manufacturing and resource management practices across industries. Continued research and development will further enhance the performance and cost-effectiveness of these units, making them even more attractive to businesses seeking sustainable solutions.

The adoption of Solvent Recycling Units is revolutionizing industries by offering a sustainable solution to solvent management. By recycling solvents on-site, businesses can enhance environmental sustainability, reduce costs, and optimize resource utilization. The versatility of Solvent Recycling Units allows for applications in manufacturing, automotive, pharmaceuticals, printing, and coating industries, among others. Moreover, by ensuring occupational health and safety, improving process efficiency, and paving the way for future advancements, Solvent Recycling Units play a pivotal role in shaping a more sustainable and prosperous future. Embracing this innovative technology is not only a responsible choice but also a strategic decision that yields long-term benefits for businesses and the planet alike. As industries continue to prioritize environmental sustainability and cost efficiency, Solvent Recycling Units will undoubtedly play a crucial role in transforming waste into opportunity.