Plant extraction using a rotary evaporator has gained significant attention in recent years due to its sustainable and efficient process. This article delves into the world of plant extraction and the pivotal role that large scale rotary evaporator play in this domain. We’ll explore the technology, methods, and environmental benefits of this approach, shedding light on how FBL Machinery and Instrument Equipment Co., Ltd. offers high-quality solutions for plant extraction.

Plant extraction, at its core, is the process of obtaining valuable compounds from plants for various applications. This encompasses natural product synthesis, essential oil extraction, and pharmaceutical production. It’s a fundamental step in the creation of a wide range of products, from herbal remedies to perfumes and pharmaceutical drugs.

The Role of Rotary Evaporators

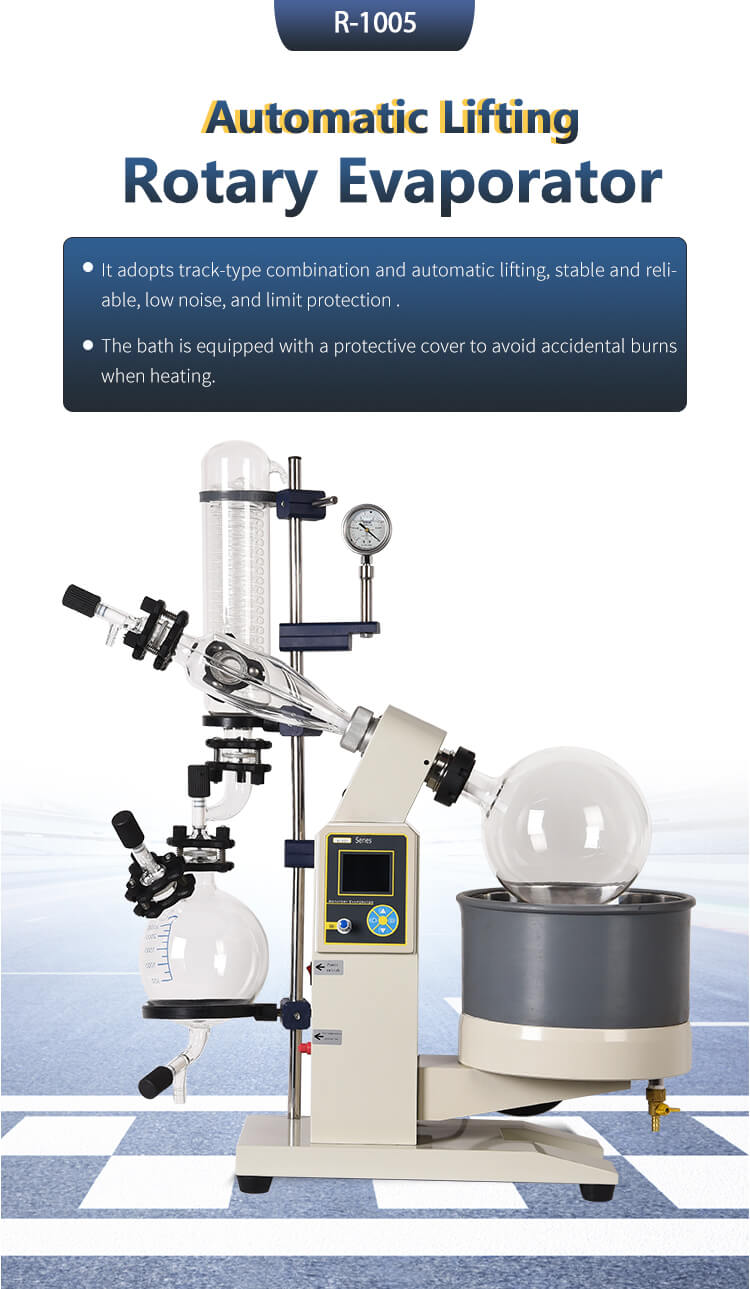

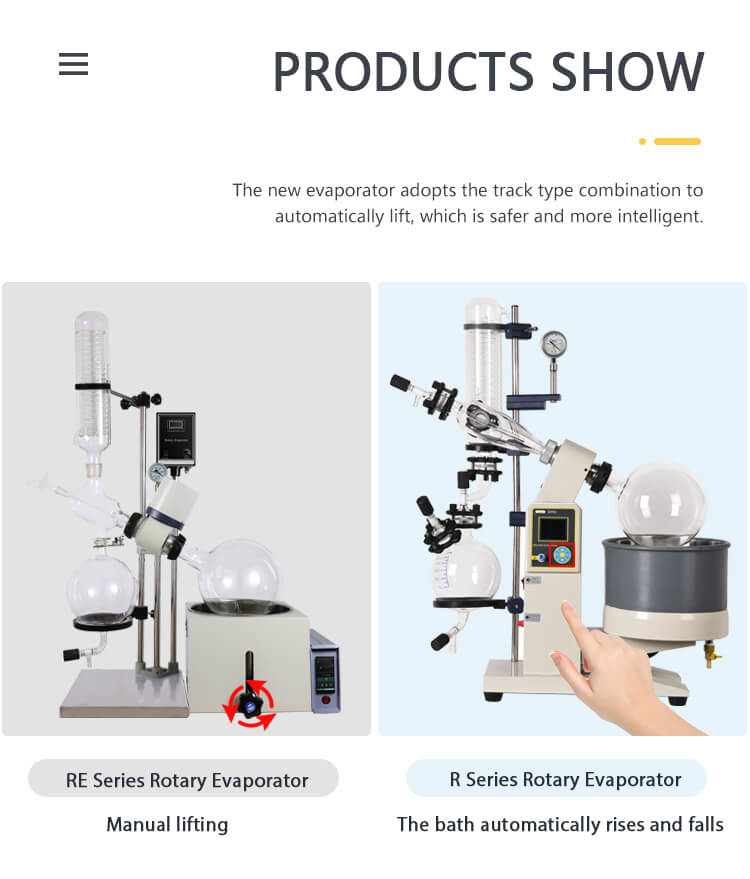

A. What Is a Rotary Evaporator?

A rotary evaporator, often referred to as a rotovap, is a device used in laboratories and industries for efficient separation of solvents from samples. It operates on the principle of reduced pressure and controlled temperature, making it an indispensable tool for plant extraction processes.

B. Key Components of a Rotary Evaporator

A rotary evaporator consists of several essential components, including a water bath or oil bath, a rotating flask, a condenser, a vacuum system, and a collection flask. Each of these components plays a crucial role in the extraction process.

C. How Does It Work?

The process begins by placing the plant material and solvent in the rotating flask. As the flask rotates, the combination is subjected to controlled heat and reduced pressure, causing the solvent to evaporate. The vapor is then condensed in the condenser and collected in a separate flask, leaving behind the extracted compounds.

Sustainable Plant Extraction

A. Reduced Environmental Impact

One of the primary advantages of plant extraction using rotary evaporators is its sustainability. The process minimizes solvent usage and energy consumption, reducing its environmental impact. This aligns with the global shift towards eco-friendly practices.

B. Energy Efficiency

Rotary evaporators are designed to be energy-efficient. By maintaining a lower temperature and pressure, they consume less energy compared to traditional extraction methods. This not only reduces operational costs but also lessens the carbon footprint.

C. Solvent Recovery

The rotary evaporator’s ability to recover and reuse solvents further enhances its sustainability. It minimizes solvent waste and conserves valuable resources, making it an eco-conscious choice for extraction processes.

Applications of Plant Extraction Using Rotary Evaporators

A. Pharmaceutical Industry

The pharmaceutical sector extensively employs plant extraction for drug development. Rotary evaporators play a pivotal role in extracting active compounds from plants, contributing to the production of medicines and herbal remedies.

B. Essential Oil Production

The fragrance and aromatherapy industries rely on plant extraction for essential oil production. The precise control offered by rotary evaporators ensures the preservation of delicate aromatic compounds.

C. Natural Product Synthesis

Researchers use plant extraction to isolate and synthesize natural products for scientific studies and various applications. Rotary evaporators enable the efficient separation and purification of these compounds.

FBL Machinery and Instrument Equipment Co., Ltd. Solutions

FBL Machinery and Instrument Equipment Co., Ltd. is a renowned supplier of high-quality rotary evaporators for plant extraction. With 13 years of export experience and a commitment to customer satisfaction, they provide tailored solutions that meet the specific needs of their clients. Their wide range of products and dedicated customer service make them a trusted choice in the field of plant extraction equipment.

Conclusion

Plant extraction using a rotary evaporator is a sustainable and efficient process that has found applications in various industries. It minimizes environmental impact, conserves energy, and offers precise control over the extraction process. FBL Machinery and Instrument Equipment Co., Ltd. stands as a reliable partner in providing high-quality rotary evaporators, making plant extraction an accessible and environmentally responsible practice for businesses worldwide.