In the world of chemical and biological pharmaceutical research, having the right equipment is crucial for success. One piece of equipment that has gained significant recognition in recent years is the glass filter reactor. This versatile apparatus is at the forefront of laboratory equipment, offering a wide range of applications across various industries. In this article, we will delve into the world of 10l jacketed glass reactor, exploring their uses, advantages, and the innovative solutions they bring to the table.

Understanding the Glass Filter Reactor

Glass filter reactors, often referred to as GFR, are specialized instruments designed for various chemical and biological processes. They are known for their transparent glass construction, allowing researchers to observe reactions in real-time. This transparency not only aids in monitoring but also ensures the reactor’s corrosion resistance, making it suitable for a variety of applications.

Glass filter reactors come in different sizes, from small-scale laboratory models to larger industrial variants. Their adaptability and scalability make them an indispensable tool for researchers, manufacturers, and pharmaceutical companies worldwide.

Key Features and Components

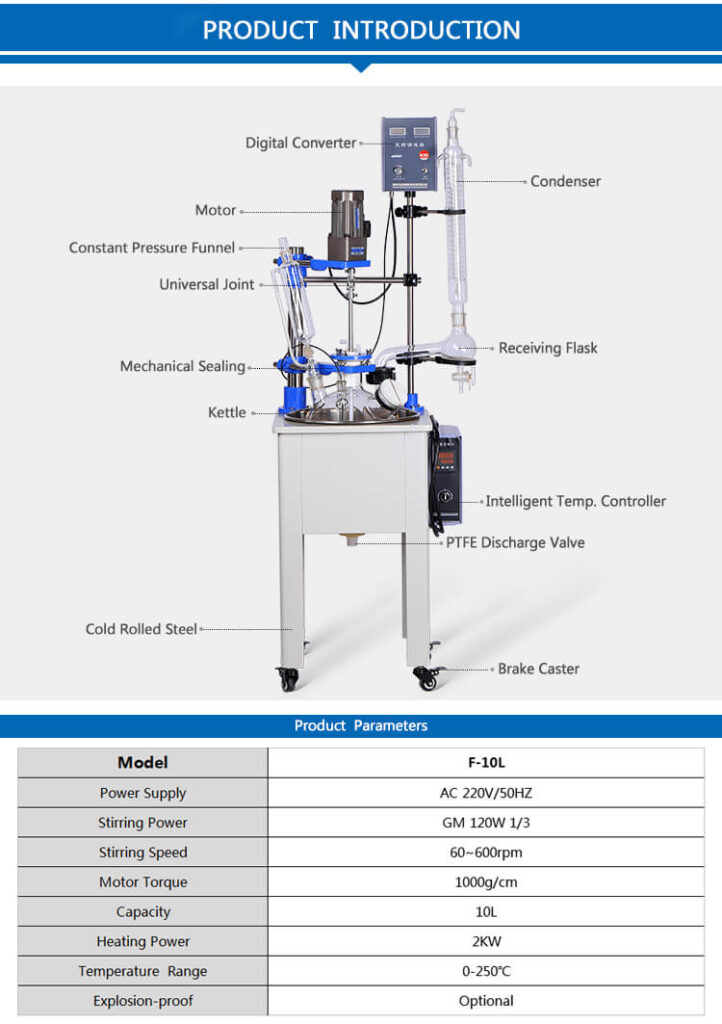

A glass filter reactor is a complex apparatus with several essential components. These include:

1. Glass Vessel: The heart of the reactor, the glass vessel, is where the chemical reactions take place. It’s made from high-quality borosilicate glass, known for its resistance to thermal shock and chemical corrosion.

2. Stirring Mechanism: Most glass filter reactors are equipped with a stirring system to ensure even mixing of reactants. This mechanism can be customized based on the specific requirements of the process.

3. Temperature Control: Precise temperature control is crucial in many reactions. Glass reactors often come with a temperature control system that allows researchers to maintain the desired reaction temperature.

Applications in the Pharmaceutical Industry

Glass filter reactors find extensive use in the pharmaceutical sector. They are employed in various processes, including:

– Chemical Synthesis: Glass reactors are ideal for the synthesis of pharmaceutical compounds, allowing researchers to closely monitor reactions and optimize processes.

– Crystallization: Precise temperature control and mixing make glass filter reactors suitable for crystallization processes, crucial in pharmaceutical formulation development.

– Pharmaceutical Quality Control: These reactors are also used for quality control tests, ensuring that pharmaceutical products meet stringent standards.

Advantages of Glass Filter Reactors

The adoption of glass filter reactors has grown significantly, thanks to their numerous advantages:

– Visibility: The transparency of glass allows researchers to visually monitor reactions, providing valuable insights.

– Corrosion Resistance: Glass reactors are highly resistant to chemical corrosion, ensuring the purity of reactions.

– Scalability: Whether you’re working on a small batch or large-scale production, glass reactors can be easily scaled up to meet your needs.

Innovations and Future Trends

As technology advances, glass filter reactors continue to evolve. New materials, such as advanced glass formulations and coatings, are being explored to enhance their performance and longevity. Additionally, automation and remote monitoring capabilities are becoming more prevalent, enabling researchers to conduct experiments with greater precision and safety.

Conclusion

In conclusion, the glass filter reactor is a versatile and indispensable piece of equipment in the world of chemical and biological pharmaceutical research. Its transparent design, corrosion resistance, and adaptability make it a go-to choice for a wide range of applications. As innovations in materials and technology continue to emerge, the future holds even greater promise for this essential laboratory tool, driving progress in scientific research and pharmaceutical development. Whether in a small laboratory or a large-scale production facility, the glass filter reactor remains a symbol of precision and reliability in the world of chemical processing.