In the world of chemical and biological pharmaceutical equipment, the ethyl acetate rotavap is a vital tool that plays a pivotal role in various processes. From extraction to distillation, this equipment has become an indispensable asset in laboratories and industries worldwide. In this comprehensive guide, we will delve into the fascinating world of large scale rotary evaporator, exploring its applications, working principles, and more. Join us on this journey as we uncover the potential of this remarkable apparatus.

The Essence of Ethyl Acetate Rotavap

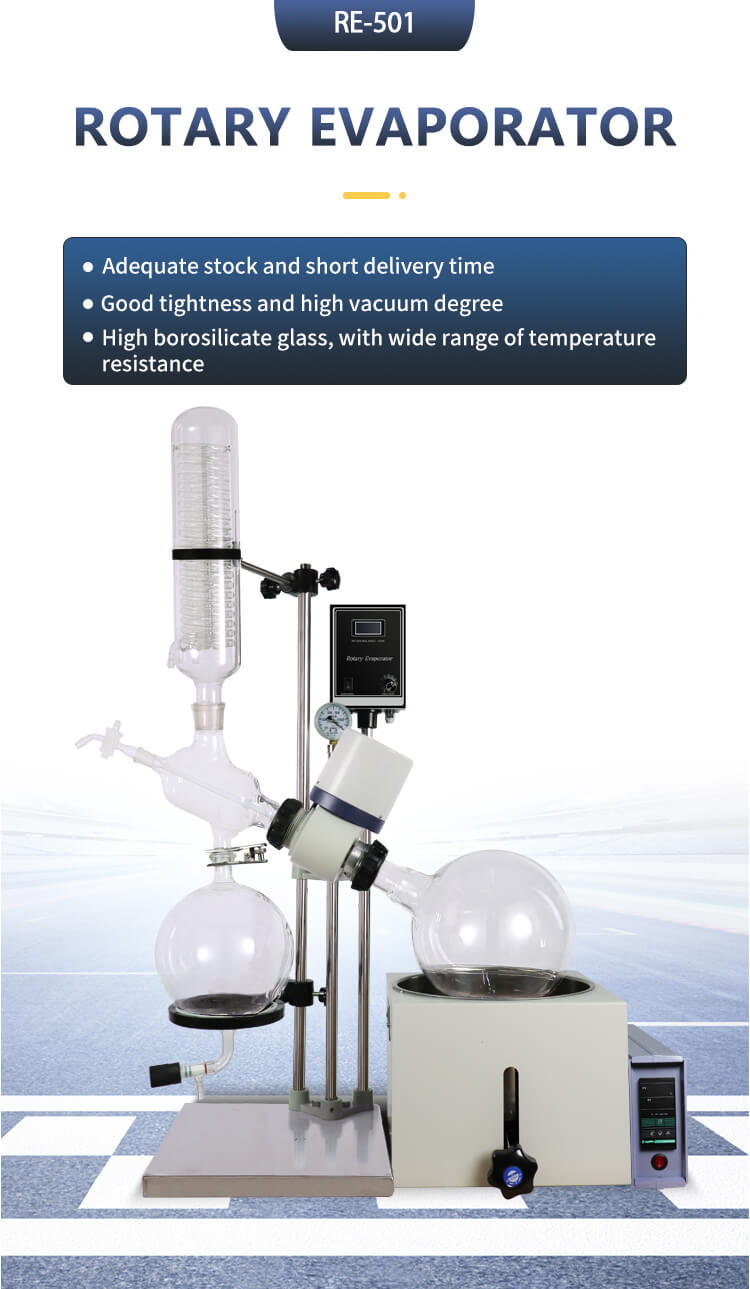

At the heart of many chemical and biological processes lies the ethyl acetate rotavap. But what is it, and how does it work? Ethyl acetate rotavap, short for “rotary evaporator,” is an essential piece of equipment in the world of chemistry. It is designed to remove solvents from solutions through the process of evaporation. This efficient method is widely employed in laboratories, pharmaceutical industries, and research centers to achieve precise separation of components.

The ethyl acetate rotavap consists of several key components, including a rotating flask, a heating bath, a condenser, and a collection flask. The sample to be concentrated or purified is placed in the rotating flask, and controlled heating and vacuum pressure facilitate solvent evaporation, leaving behind the desired substance.

This versatile equipment can be used for various applications, such as concentration, distillation, and drying, making it an indispensable asset in chemical and pharmaceutical processes.

Ethyl Acetate in the Spotlight

Ethyl acetate, a commonly used solvent, takes center stage in the operation of the ethyl acetate rotavap. It is a colorless, sweet-smelling liquid known for its low toxicity and pleasant aroma, often used in food flavoring and as an industrial solvent.

The concentration of ethyl acetate in the process can vary, and in this guide, we’ll explore the implications of different concentration levels, ranging from 0.5% to 3%.

The choice of ethyl acetate concentration can significantly impact the efficiency and outcome of the rotavap process. Let’s delve deeper into how different concentrations affect the results.

Ethyl Acetate Rotavap Applications

The applications of the ethyl acetate rotavap are diverse and far-reaching. It finds extensive use in the extraction of valuable compounds from plant materials, the purification of chemical substances, and the concentration of samples for analytical testing.

In pharmaceutical research and development, the rotavap is instrumental in the creation of pharmaceutical products and the isolation of active ingredients from natural sources.

Moreover, industries such as food and beverage, essential oil production, and environmental testing also rely on the ethyl acetate rotavap for various processes.

Operational Efficiency

Operational efficiency is a key consideration in any laboratory or industrial setting. The ethyl acetate rotavap excels in this regard, offering precise control over temperature and pressure, resulting in reduced processing times and improved product quality.

The rotavap’s ability to work with a wide range of solvents, including ethyl acetate, ensures its adaptability to diverse applications, making it a valuable asset for those seeking efficiency without compromising quality.

The combination of high-speed rotation, controlled heating, and vacuum technology provides an efficient and precise means of solvent removal, enhancing the productivity of processes.

Ethyl Acetate Rotavap Worldwide

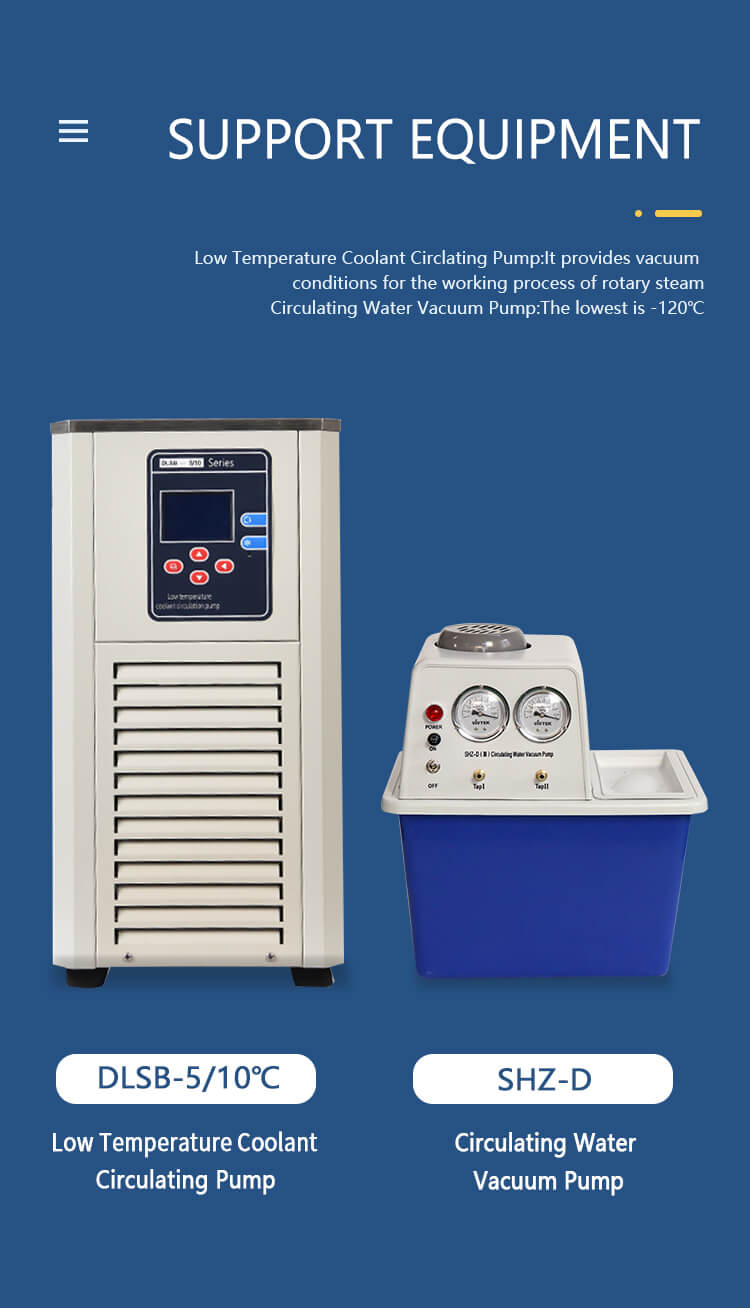

The demand for ethyl acetate rotavap is not limited by borders; it has gained recognition and popularity across the globe. Companies like ZZKD Machinery and Instrument Equipment Co., Ltd., with their extensive export experience, have played a crucial role in making this equipment accessible worldwide.

With warehouses strategically located in the United States, Spain, and Thailand, the global availability of ethyl acetate rotavap equipment has become more convenient, contributing to its widespread use.

The trust and support from customers around the world have made the ethyl acetate rotavap a symbol of reliability and innovation, driving its continuous development and improvement.