Acetone, a widely used solvent in various industries such as chemicals, pharmaceuticals, and automotive manufacturing, presents a significant challenge when it comes to waste management. Improper disposal of acetone waste not only contributes to environmental pollution but also leads to substantial economic losses for businesses. Fortunately, the development of thinner recycling machine has provided a sustainable solution to address these issues. These innovative machines leverage advanced technologies to efficiently recover and purify acetone, offering numerous benefits to industries and the environment. In this article, we will explore the working principle, diverse applications, and the advantages of utilizing acetone recycling machines. Additionally, we will examine a real-life application case that showcases the transformative potential of these machines in industrial settings.

Key Components of Acetone Recycling Machines

Waste Collection System: Gathers and directs acetone-containing waste into the machine.

Evaporation Chamber: Utilizes heat to evaporate the acetone, separating it from other waste components.

Condensation Unit: Cools and condenses the evaporated acetone, transforming it into a liquid state.

Distillation Column: Enhances purification by further separating impurities from the condensed acetone.

Filtration System: Removes any remaining impurities or particulate matter, ensuring the purity of the recycled acetone.

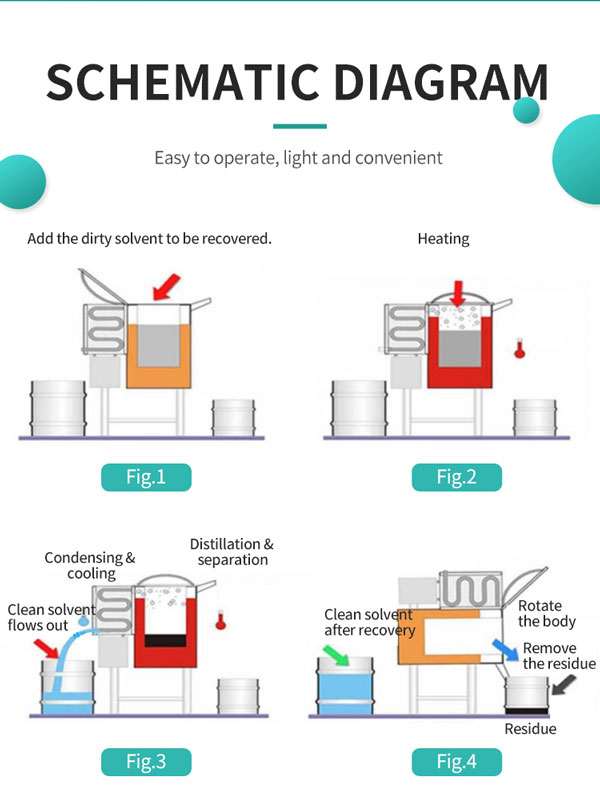

Working Principle of Acetone Recycling Machines

Evaporation and Condensation: The Core Process

Acetone recycling machines employ the principle of evaporation and condensation to separate acetone from other waste substances. The waste stream containing acetone is heated in the evaporation chamber, causing the acetone to vaporize while leaving behind non-volatile waste materials. The resulting vapor is then directed to the condensation unit, where it is cooled and converted back into a liquid form. This condensed acetone is collected and further purified through distillation and filtration processes, ensuring its quality and removing any remaining impurities. The purified acetone is then stored for reuse in industrial processes, significantly reducing the need for new acetone procurement.

Applications of Acetone Recycling Machines

Chemical Industry:

Acetone is widely used in the production of various chemicals. Acetone recycling machines enable chemical manufacturers to recover and reuse this valuable solvent, leading to a substantial reduction in waste generation and disposal costs. Additionally, by recycling acetone, companies can lower their reliance on fresh acetone procurement, resulting in significant cost savings.

Pharmaceutical Industry:

The pharmaceutical industry extensively utilizes acetone in processes such as drug formulation and cleaning equipment. Acetone recycling machines offer pharmaceutical companies a sustainable solution to manage their acetone waste efficiently. By implementing these machines, pharmaceutical manufacturers can contribute to environmental sustainability by minimizing the release of hazardous waste into the environment while also optimizing resource utilization and reducing costs.

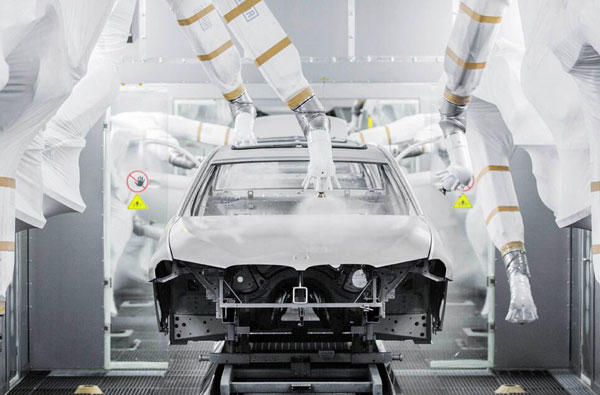

Automotive Industry

The automotive industry relies on acetone-based paints and coatings for manufacturing and refinishing operations. Acetone recycling machines offer automotive companies an efficient means to recover and reuse acetone from their waste streams. By implementing these machines, the industry can reduce the consumption of fresh acetone, optimize costs, and minimize the environmental impact associated with the disposal of acetone waste.

Benefits of using acetone recycling machine

Environmental Benefits

Acetone recycling machines significantly decrease the volume of hazardous waste generated by industries. By recovering and reusing acetone, the machines minimize the amount of waste that would otherwise require disposal, thereby reducing the environmental burden.

Minimization of Air and Water Pollution

The proper management of acetone waste through recycling machines helps prevent the release of volatile organic compounds (VOCs) into the atmosphere, thus reducing air pollution. Furthermore, by purifying and treating acetone waste, these machines prevent the contamination of water sources, ensuring the preservation of water quality and ecosystem integrity.

Economic Benefits

Acetone recycling machines allow businesses to recover and reuse acetone, reducing their reliance on fresh acetone procurement. This significantly cuts down the expenses associated with purchasing new acetone, resulting in substantial cost savings.

Reduced Disposal Costs

Proper disposal of acetone waste can be expensive due to its classification as hazardous waste. By implementing acetone recycling machines, businesses can minimize the volume of waste requiring disposal, thereby reducing disposal costs and associated regulatory compliance expenses.

Sustainability and Corporate Social Responsibility

Acetone recycling machines align with sustainability goals by promoting waste reduction and resource conservation. By implementing these machines, companies demonstrate their commitment to environmental stewardship and contribute to a more circular economy.

Enhancing Brand Reputation

Adopting acetone recycling machines showcases a company’s commitment to sustainable practices, which can positively influence customer perception and brand reputation. By actively addressing environmental concerns and implementing eco-friendly solutions, businesses can enhance their corporate social responsibility efforts, attract environmentally conscious customers, and differentiate themselves in the market.

Application Case: Acetone Recycling Machine in XYZ Chemical Company

XYZ Chemical Company is a leading manufacturer of specialty chemicals with a strong commitment to sustainability and environmental responsibility. The company’s operations involve the use of acetone in various processes, resulting in the generation of substantial acetone waste.

Implementation of Acetone Recycling Machine

Selecting and Installing the Recycling Machine

XYZ Chemical Company conducted thorough research to identify a suitable acetone recycling machine that aligned with their operational needs and sustainability goals. They selected a state-of-the-art machine that offered advanced distillation and purification capabilities.

Training and Integration into Existing Processes

The company ensured that their employees received comprehensive training on operating and maintaining the acetone recycling machine. They integrated the machine into their waste management infrastructure, streamlining the collection and processing of acetone waste.

Results and Benefits Achieved

Reduction in Waste Disposal Costs

By implementing the acetone recycling machine, XYZ Chemical Company significantly reduced their expenses associated with disposing of acetone waste. The volume of waste requiring disposal decreased, leading to cost savings and improved financial performance.

Lowered Environmental Footprint and Regulatory Compliance

The company achieved their environmental objectives by effectively managing their acetone waste. The recycling machine enabled them to minimize the release of hazardous waste into the environment, ensuring compliance with environmental regulations and reducing their ecological impact.