Product Introduction Of Rotary Evaporator Machine

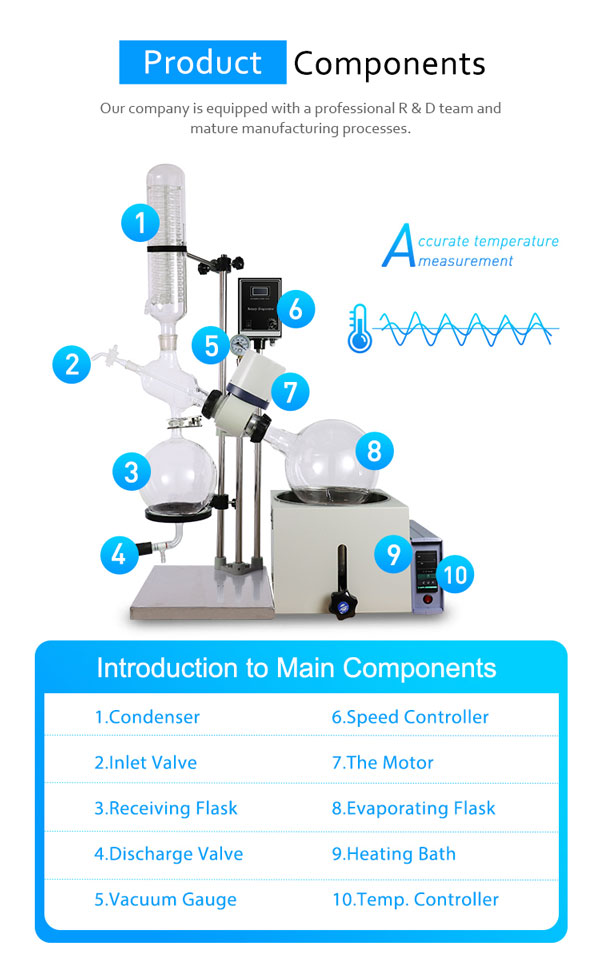

Re-501 rotary evaporator is a small rotary evaporator with a capacity of 5L in the evaporating bottle, a capacity of 3L in the receiving bottle, a speed of 0-90R/min, and a motor power of 40W. Rotary evaporator machine consists of three parts: heating device, rotary evaporator, cooling recovery device. The principle is: under the condition of negative pressure, the constant-temperature heated water bath rotates at a constant speed, so that the material forms a large-area film on the wall of the rotating bottle, thereby improving the evaporation efficiency.

Grouped Equipment Of Rotary Evaporator Machine

DLSB-5/30 low temperature coolant circulation pump

Capacity: 5L; Minimum no-load temperature: -30°C; Power 100W

(DLSB-5/40; DLSB-10/10)

SHZ-D(Ⅲ) Desktop Vacuum Pump

Capacity: 15L; Maximum vacuum: 70kpa

Product Features Of Rotary Evaporator Machine

(1) Sealing parts: use the latest polytetrafluoroethylene and high-quality fluororubber materials, which are processed by special technology to enhance sealing, corrosion resistance and wear resistance

(2) Collection system: A new type of automatic switching valve is adopted, which can carry out continuous collection without affecting the system vacuum and solution distillation.

collect

(3) Main structure: It is made of high-quality steel and 304 stainless steel, and the appearance is fully sprayed with plastic, which is more perfect and improves the reasonable performance of the instrument.

(4) Rotary evaporator machine with high evaporation efficiency and high recovery rate;

(5) Rotary evaporator machine is easy to assemble and disassemble, easy to operate and easy to maintain;

(6) Rotary evaporator machine has a stainless steel chassis, columns, and vertical shafts, with beautiful appearance and corrosion resistance;

(7) Unique sealing structure and selected sealing materials, strong corrosion resistance, can maintain a vacuum degree above -0.096MPA

(8) Re-501 rotary evaporator adopts AC induction motor, stepless speed regulation, no brush, no spark, long life.

(9) Re-501 rotary evaporator can work without interruption, high evaporation rate, high recovery rate, advanced frequency conversion, electronic speed control device

(10) The glass instrument is made of GG-17 high borosilicate glass with good physical and chemical properties.

(11) Well-designed special sealing system, excellent corrosion resistance, vacuum degree -0.096Mpa or more

Applications Of Rotary Evaporator Machine

Re-501 rotary evaporator can be heated at a constant temperature and rotated to form a film under negative pressure conditions, and at the same time evaporate the solvent and condense for recovery. It is especially suitable for concentration, crystallization, separation and recovery of heat-sensitive substances. It is an important equipment for scientific research and pilot production in biopharmaceutical, chemical, food and other industries.

Installation Process Of Rotary Evaporator Machine

Preparations

Take the stainless steel bottom plate, vertical rod, bolts and nuts, vacuum gauge and gauge rod, condenser fixing rod out of the packing box, and place them on the operating table stably.

Install the pole

Assemble the vacuum gauge, gauge rod, and condenser fixing rod to the vertical rod; fix the assembled vertical rod on the stainless steel bottom plate with bolts and nuts, and make the front of the vacuum gauge face the installer. Once assembled, place the rack flat on the work bench.

Install the host

Install the host on the base of the machine head; tilt to the right about 45°C; lock the screws on the frame.

Install the glass shaft

Put the glass through-shaft into the host; install PTFE gaskets at both ends of the glass through-shaft.

Install the glass part

Fix the four-way bottle on the machine head with a flange. Connect the condenser to the four-way bottle, and make the joints of the condenser backward. Secure the condenser to the pole with the condenser retaining ring.

Connect the PTFE tube to the feeding valve, and then install it to the left port of the four-way bottle;

Dock the receiving bottle with the lower mouth of the four-way bottle, and clamp it with the bottle mouth clip;

Fix the bottle support ring on the pole with screws, adjust the height, and stabilize the collection bottle;

Use the flange to fix the rotating bottle on the right end of the rotating shaft;

Place the water bath under the spinner bottle, and add 2/3 of water or heat transfer oil to the pot.

Install the speed control box

Fix the speed control box on the pole, and plug in the five-pin plug of the motor. With the front of the governor box facing the installer.

Parameter

| Mol | Rotating Motor(W) | Water(Oil) Bath Power(W) | Temperature Control Range | Evaporation Rate(H2O) | Voltage | Lifing Height(mm) |

| RE-2000B | 40 | 1500 | RT~99℃ | ≥1L/h | 220V/50HZ | 0~140 |

| RE-5299 | 30 | 1500 | RT~99℃ | ≥1L/h | 220V/50HZ | 0~150 |

| RE-201D | 40 | 1200 | RT~399℃ | ≥1L/h | 220V/50HZ | 0~150 |

| RE-301 | 40 | 1500 | RT~399℃ | ≥1.5L/h | 220V/50HZ | 0~120 |

| RE-501 | 40 | 1500 | RT~399℃ | ≥1.5L/h | 220V/50HZ | 0~120 |

| RE-1002 | 180 | 3000 | RT~99(250)℃ | >3L/h | 220V/50HZ | 0~220 |

| RE-2002 | 180 | 5000 | RT~99(250)℃ | >5L/h | 220V/50HZ | 0~220 |

| RE-5002 | 250 | 7000/9000 | RT~99(250)℃ | >9L/h | 380V/50HZ | 0~220 |

| RE-2000B | 40 | 1500 | RT-99 Temperature control accuracy ±1℃ | ≥1 | 220V 50/60HZ | 0-140 |

| EXRE-1002 | 180 | 3000 | 0-99(250) | >3 | 220V 50/60HZ | / |

| EXRE-2002 | 180 | 5000 | 0-99(250) | >5 | 220V 50/60HZ | / |

| EXRE-5002 | 370 | 7000/9000 | 0-99(250) | >9 | 380V/50HZ | / |

| Model | Rotating Motor(W) | Water(Oil) Bath Power(W) | Temperature Control Range |

| RE-2000B | 40 | 1500 | RT~99℃ |

| RE-5299 | 30 | 1500 | RT~99℃ |

| RE-201D | 40 | 1200 | RT~399℃ |

| RE-301 | 40 | 1500 | RT~399℃ |

| RE-501 | 40 | 1500 | RT~399℃ |

| RE-1002 | 180 | 3000 | RT~99(250)℃ |

| RE-2002 | 180 | 5000 | RT~99(250)℃ |

| RE-5002 | 250 | 7000/9000 | RT~99(250)℃ |

| RE-2000B | 40 | 1500 | RT-99 Temperature control accuracy ±1℃ |

| EXRE-1002 | 180 | 3000 | 0-99(250) |

| EXRE-2002 | 180 | 5000 | 0-99(250) |

| EXRE-5002 | 370 | 7000/9000 | 0-99(250) |

FAQ

Q: What is the reason why the power indicator light is not on after the instrument is powered on?

Answer: If the power cord is not connected or wrongly connected, just connect the power cord; if the power switch or circuit board fails, stop using it immediately and contact us or professional maintenance personnel.

Q: What is the reason why the motor of Re-501 rotary evaporator does not rotate?

Answer: If the indicator light of the electric control box is on, you should check whether the internal and external plugs in the electric box are loose or disconnected, re-insert the plug, and connect the disconnected line; if the indicator light or digital display of the electric control box is not on, you should replace the fuse Or confirm that there is no abnormality in the power supply; if the inverter is disturbed by high frequency and displays “O.U.”, just troubleshoot according to the instruction manual of the inverter.

Q: Why does the rotary evaporator machine make abnormal sounds during use?

Answer: It may be that the sealing ring is worn, just replace it with a new one; it may also be that the internal gear is worn, the driving part is short of oil, or the motor is faulty. In this case, stop using it immediately and contact us or a maintenance engineer.