Basic principle of rotary evaporator

Definition and Uses of Rotary Evaporation

How rotary evaporator works?Rotary evaporation is a commonly used separation and concentration technique widely used in chemical laboratories and industrial fields. It is based on the principle of evaporation of liquids under heated conditions and is achieved by a rotary evaporator. In rotary evaporation, a liquid sample is placed in a round bottom flask or flask holder on a rotary evaporator. By heating and rotating the flask, the liquid sample is rapidly evaporated to form a gas or vapour. At the same time, the rotating motion of the rotary flask makes the evaporation surface constantly renewed, thus improving the evaporation efficiency. The gas or vapor produced by evaporation is usually collected by condensation for subsequent analysis or concentration.

Applications of rotary evaporator

Rotary evaporation has a wide range of applications in many laboratory and industrial fields. Here are some common uses for rotary evaporators:

Solvent removal and concentration:

Rotary evaporation can be used to remove or concentrate solvents so that the volume of the sample or solution is reduced while concentrating the target species.

Sample Preparation:

In chemical synthesis, rotary evaporation can be used to prepare and purify organic compounds. By removing the solvent, pure compounds can be obtained for further experiments or analysis.

Sample separation:

Rotary evaporation can separate the components in the mixture, and realize the separation and purification of compounds according to their volatility differences.

Extraction and Leaching:

Rotary evaporation can be used for solvent removal and concentration of target substances in extraction and leaching processes, such as the preparation of herbal extracts.

Solvent recovery:

Rotary evaporation can be used to recover and reuse solvents, reducing solvent waste and costs in chemistry laboratories.

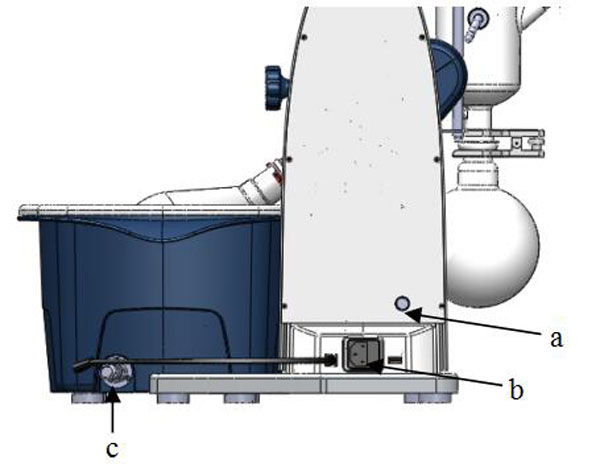

B. Components of a rotary evaporator

Rotary evaporating flask (Flask):

A rotary evaporating flask is a round bottom flask, usually made of glass.

Rotary Drive (Rotary Drive):

The rotary drive is the core component of the rotary evaporator, usually located on the top of the instrument.

Water bath or heating device (Water Bath/Heating Device):

In order to provide heating and evaporation of the sample, the rotary evaporator is usually equipped with a water bath or heating device. water

Temperature Control System:Control Panel:

The control panel is located on the front or top of the rotary evaporator, providing control and adjustment of parameters such as rotation speed, heating temperature, and vacuum degree.

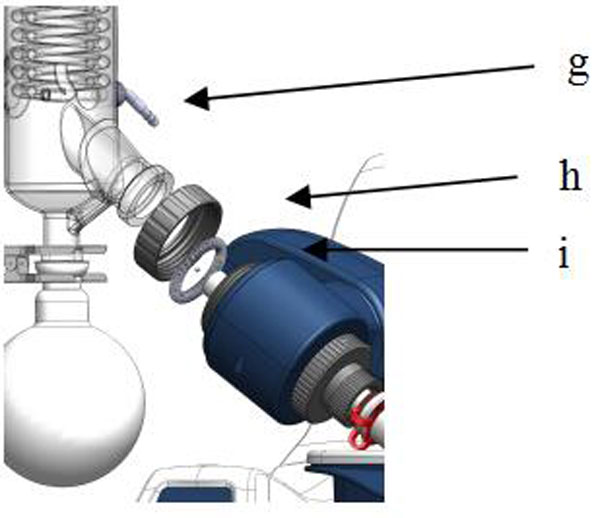

Condenser:

The condenser is used to condense the evaporated gas or vapor into a liquid in order to collect and separate the target substance.

Vacuum System:

In some rotary evaporators, a vacuum system is equipped to decompress and control the pressure of the evaporation environment.

Control Panel:

The control panel is located on the front or top of the rotary evaporator, providing control and adjustment of parameters such as rotation speed, heating temperature, and vacuum degree.

Operation steps

Prepare samples: Prepare liquid samples to be evaporated according to experimental requirements. Make sure the sample has been filtered or treated to remove suspended solids or impurities.

Choose the right container: Choose the right vial or flask, depending on the size and chemical nature of the sample volume.

Sample treatment: If required, pretreatment steps such as dissolution, dilution, or pH adjustment can be performed to better suit the conditions of the rotary evaporation.

Install vials and evaporating flasks:

Place the rotavapor on the rotary drive of the rotavapor and make sure it is securely fastened.

Transfer the sample to the sample vial, making sure that the sample fills the vial and does not overflow. Secure the sample vial to the neck of the rotary evaporating flask.

Set the parameters of the rotary evaporator:

Rotation speed: Set the rotation speed according to the nature of the sample and the experimental requirements. In general, higher spin speeds increase evaporation efficiency, but may also introduce a risk of sample splashing.

Heating temperature: Set an appropriate heating temperature according to the boiling point and stability of the sample. Make sure that the heating temperature does not cause decomposition or overheating of the sample.

Vacuum level: If the rotary evaporator is equipped with a vacuum system, set the appropriate vacuum level to reduce the ambient pressure. Lower pressures help to speed up evaporation, but also be aware of volatile loss of the sample.

Start and monitor the rotary evaporation process:

Start up the instrument: Start up the rotary evaporator according to the instrument’s operating manual and ensure that all parameters are set correctly.

Monitor Evaporation Process: Keep an eye on the evaporation process of the sample. Observe that the sample is evenly rotated and evaporated to ensure that no splashing or overheating occurs. At the same time, record the time of evaporation and observe the change of the sample.

Collect and process evaporated samples:

Condensation collection: The evaporated gas or steam is condensed into liquid through the condenser and collected into the corresponding container. Make sure the condenser is connected to the cooling water source and keep the cooling water flowing.

Sample processing: According to the experimental requirements, the evaporated samples are further processed. Concentration, dilution, filtration, etc. steps can be performed to obtain the desired final sample.

During the entire operation process, be sure to follow the safety regulations and personal protection requirements of the laboratory to ensure the safety of the operating environment. At the same time, according to the specific rotary evaporator model and the guidance of the operation manual, carry out specific adjustments to the operation steps and follow the precautions.