Rotary evaporators, often called rotovaps, are indispensable tools in various industries, particularly in laboratories and research settings. They serve a crucial role in separating solvents from substances through evaporation. In this comprehensive guide, we will delve into the inner workings of large scale rotary evaporator, exploring their components, operation, and diverse applications.

Understanding the Basics of Rotary Evaporation

Before delving into the intricate details of how a rotary evaporator operates, let’s start with the fundamentals. At its core, a rotary evaporator is designed for the gentle and efficient removal of solvents from samples through the process of evaporation. It consists of several key components, including a rotating flask, a heated water bath, a condenser, and a vacuum system.

The process initiates with the placement of the sample in the rotating flask. This flask is connected to a motor that rotates it slowly, creating a thin film of the sample on the inner surface. Simultaneously, the heated water bath provides a controlled source of heat, expediting the evaporation process.

Evaporation and Condensation: The Dynamic Duo

The heart of the rotary evaporator lies in its ability to promote both evaporation and condensation. As the flask rotates and the sample heats up, the solvent within it begins to evaporate into vapor form. This vapor is then directed into the condenser, a coiled tube typically cooled by circulating cold water or a refrigeration system.

Inside the condenser, the vapor encounters a significantly cooler environment, causing it to condense back into a liquid state. As a result, the solvent is effectively separated from the sample material and collects in a separate flask or container. This condensation process is crucial for recovering and reusing valuable solvents.

The Role of Vacuum: Reducing Boiling Points

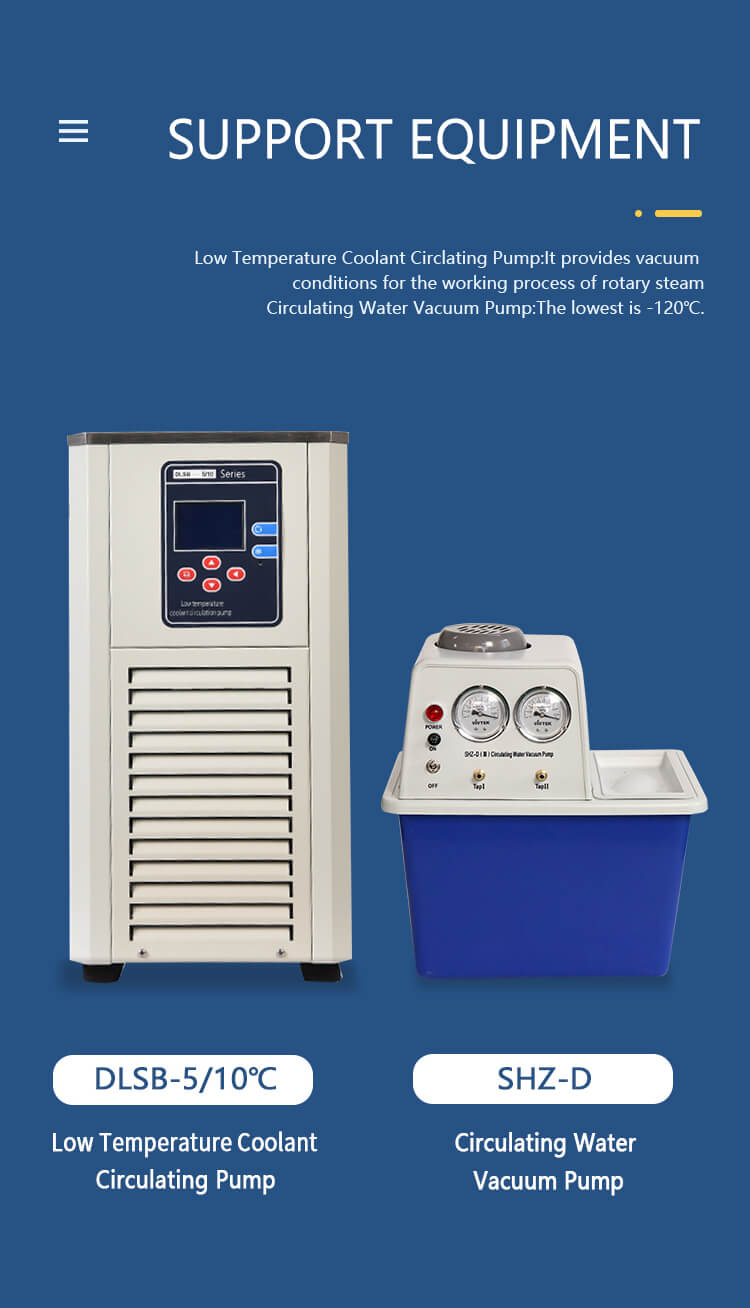

An essential feature of rotary evaporators is their ability to operate under vacuum conditions. The vacuum system plays a pivotal role in lowering the pressure within the system, thereby reducing the boiling point of the solvent. This allows for the evaporation of solvents at lower temperatures, minimizing the risk of heat-induced damage to sensitive samples.

Typically, a vacuum pump is employed to control the level of vacuum throughout the process. This feature proves especially beneficial when working with volatile or heat-sensitive substances.

Precise Control: Tailoring the Process

Precise control is paramount when utilizing a rotary evaporator. Researchers have the flexibility to adjust various parameters, including the rotation speed of the flask, the temperature of the water bath, and the vacuum level. These controls enable customization of the evaporation process to suit the specific requirements of the sample and solvent being used.

Diverse Applications of Rotary Evaporators

Rotary evaporators have an extensive range of applications across various industries and research fields. In chemistry laboratories, they are indispensable for concentrating solutions, purifying compounds, and preparing samples for analysis. Pharmaceutical companies rely on rotary evaporators in drug development, particularly in the production of active pharmaceutical ingredients (APIs).

Chemistry and Analytical Laboratories

In chemistry and analytical laboratories, rotary evaporators are indispensable tools for a multitude of applications. They are commonly used for:

1. Solvent Recovery: Rotary evaporators efficiently recover solvents from reaction mixtures, minimizing waste and environmental impact.

2. Concentration: Concentrating dilute solutions, such as natural extracts or synthesized compounds, to increase their potency or purity.

3. Purification: Purifying substances by removing impurities or undesirable components through solvent evaporation.

Pharmaceutical and Biotechnology Industries

The pharmaceutical and biotechnology sectors heavily rely on rotary evaporators for various purposes, including:

1. API Production: Rotary evaporators play a vital role in producing high-purity active pharmaceutical ingredients used in drug formulations.

2. Formulation Development: Researchers use rotovaps to create concentrated drug formulations with precise specifications.

3. Herbal Extracts: In herbal medicine and nutraceuticals, rotary evaporators are employed to extract and concentrate bioactive compounds from plants.

Food and Beverage Industry

In the food and beverage industry, rotary evaporators find application in:

1. Flavor Extraction: Capturing and concentrating flavors and fragrances from natural sources for use in food and beverage products.

2. Alcohol Recovery: Removing solvents or alcohol from food products or extracts to meet regulatory standards.

3. Research and Development: Developing innovative food and beverage products by concentrating or purifying key ingredients.

Conclusion: A Crucial Component in Laboratories and Industries

In conclusion, rotary evaporators are versatile and indispensable tools in laboratories and industries. Their ability to gently and efficiently remove solvents through controlled evaporation makes them invaluable for various applications. Whether you are working in chemistry, pharmaceuticals, food science, or any field requiring solvent separation, the rotary evaporator is a cornerstone of your laboratory equipment.

Understanding the intricate workings of rotary evaporators empowers researchers and professionals to optimize their processes, achieve precise results, and contribute to advancements in their respective fields. With their significant impact on efficiency and sustainability, rotary evaporators are poised to remain essential components of scientific and industrial endeavors for years to come.