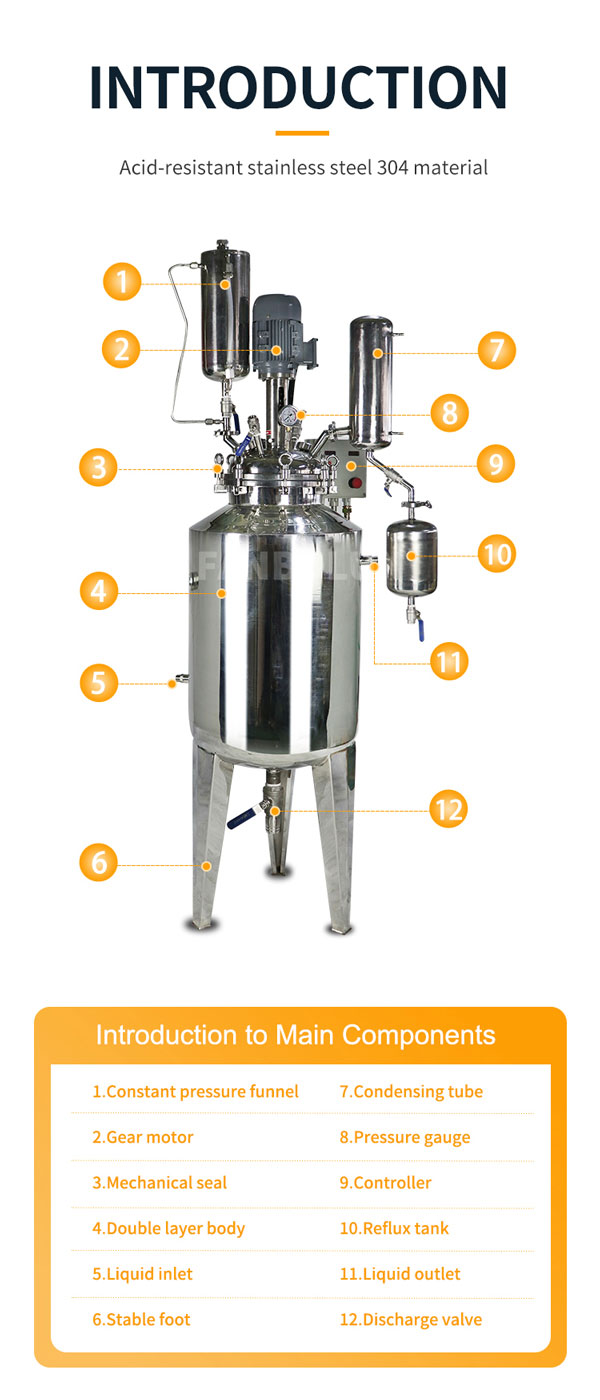

Introduction to SS Reactor

SS-100L SS Reactor is also called “stainless steel reactor”, with a capacity of 100L, it is a vessel or container used in various chemical processes, in which reactants are mixed to produce the desired chemical reaction. This equipment can be used in a range of chemical processes including chemical synthesis, polymerization and petrochemical processing.

SS Reactor features

Material:

The stainless steel reactor is made of stainless steel, which has excellent corrosion resistance and durability, and can withstand high temperature and high pressure.

Design:

SS Reactors can be designed to meet specific process requirements, including different shapes and sizes, heating and cooling options, and agitation systems.

Versatility:

SS Reactors are versatile and can be used in a range of chemical processes including chemical synthesis, polymerization and biodiesel production.

Durability:

SS Reactors are designed to withstand harsh chemical environments and will last for many years with proper care and care.

Safety:

The SS Reactor is designed with safety in mind, including features such as pressure relief valves, temperature sensors and monitoring systems.

Easy to clean:

Stainless steel is easy to clean and sanitize, making SS Reactors ideal for the food processing and pharmaceutical industries.

Scalability:

The SS Reactor can be scaled up or down to suit different process requirements, from small laboratory-scale reactors to large industrial-scale reactors.

Application of SS Reactor

Chemical synthesis:

SS Reactors are commonly used in chemical synthesis reactions in which reactants combine to form new compounds.

Polymerization:

SS Reactors are used in the production of polymers such as plastics, rubber and synthetic fibers.

Biodiesel Production:

The SS Reactor is used to produce biodiesel from vegetable oil or animal fat.

Petrochemical processing:

SS Reactors are used in petrochemical processing to refine crude oil into useful products such as gasoline, diesel and

Other chemicals.

Pharmaceutical manufacturing:

SS Reactors are used in pharmaceutical manufacturing to produce drugs, vaccines and other medical products.

Food processing:

SS Reactors are used in food processing to produce ingredients such as flavorings, colors and preservatives.

Water treatment:

SS Reactors are used in water treatment to remove pollutants and purify water for human consumption.

SS Reactor operating procedures

- Before the stainless steel reactor works

- Check whether the interior of the kettle, agitator, rotating parts, auxiliary equipment, indicating instruments, safety valves, pipelines and valves meet the safety requirements.

- Check whether the water, electricity and gas meet the safety requirements.

Second, the stainless steel reactor is working

- Turn on the agitator of the reaction kettle before adding materials. When there is no noise and normal, add the materials into the reaction kettle. The amount of materials added must not exceed the process requirements. the

- Before opening the steam valve, first open the return valve, and then open the intake valve. Open the steam valve slowly to preheat the jacket and increase the pressure gradually. The pressure in the jacket must not exceed the specified value. the

- The steam valve and cooling valve cannot be activated at the same time, and hammering and collision are not allowed when the steam pipeline passes through the gas. the

- When opening the cooling water valve, open the return valve first, and then open the water inlet valve. The cooling water pressure shall not be lower than 0.1 MPa, nor higher than 0.2 MPa. the

- For water ring vacuum pumps, the water should be supplied after the pump is started. When the pump is stopped, the pump should be stopped first and then the water should be stopped, and the accumulated water in the pump should be removed. the

- Check the operation of the reactor at any time, and stop the reactor for maintenance if abnormalities are found. the

- When cleaning the titanium epoxy (enamel) reactor, it is not allowed to brush the reactor with alkaline water, and be careful not to damage the enamel.

- The stainless steel reactor stops working

- Stop stirring, cut off the power supply, and close various valves. the

- When shoveling the pot, the power supply of the mixer must be cut off, a warning sign should be hung, and someone should be supervised. the

- The stainless steel reactor must undergo regular technical inspection according to the requirements of the pressure vessel. If the inspection fails, it must not be operated.

Parameter

| — PARAMETER — | |||

| Model | SS-100L | Power | 400W |

| Capacity | 100L | Frequency | 0-500 r/min |

| Jacket capacity | 30L | Maximum torque | 273 N/CM |

| Voltage | 220V/50HZ | Heating mode | Sandwich oil bath |

| Working pressure | Ordinary pressure | Material | 304/316 |

| temperature | 0-250℃ | Sealing mode | Mechanical seal |

FAQ

Q: What is SS Reactor?

A: SS Reactor is a reactor made of stainless steel. It is used in various chemical processes including chemical synthesis, polymerization and biodiesel production.

Q: What are the advantages of using SS Reactor?

A: The advantages of using SS Reactor include its corrosion resistance and ability to withstand high temperature and high pressure. This makes it a durable and reliable choice for a range of industrial applications.

Q: What is the difference between SS Reactor and glaSS Reactor?

A: The main difference between SS Reactor and glaSS Reactor is their manufacturing materials. Stainless steel reactors are made of stainless steel while glaSS Reactors are made of borosilicate glass. GlaSS Reactors are generally used for small scale reactions, while stainless steel reactors are used for larger scale reactions.