Solvent recovery distillation units play a crucial role in various industries, including the chemical and pharmaceutical sectors. These innovative pieces of equipment are designed to efficiently and effectively recover solvents used in industrial processes. In this article, we will delve into the world of solvent recovery distillation units, exploring their significance, operation, benefits, and applications.

I. Understanding Solvent Recovery Distillation Units

Before we delve into the specifics of solvent recovery distillation units, it’s essential to grasp the concept of solvent recovery itself. Solvents are widely used in industries for various purposes, such as cleaning, extraction, and chemical reactions. However, the disposal of spent solvents can be costly and environmentally unfriendly. Solvent recovery aims to address these challenges by reclaiming and reusing solvents, reducing waste, and saving resources.

II. How Solvent Recovery Distillation Units Work

Solvent recovery distillation units employ a sophisticated distillation process to separate solvents from the substances they have been used on. This process relies on the differences in boiling points between the solvents and the materials they are mixed with. The unit heats the solvent mixture, causing the solvents to vaporize. These vapors are then condensed back into liquid form, leaving behind the purified solvents.

III. Advantages of Using Solvent Recovery Distillation Units

1. Environmental Benefits

Solvent recovery distillation units significantly contribute to environmental sustainability by reducing solvent waste and emissions. This eco-friendly approach aligns with the global push for greener industrial practices.

2. Cost Savings

One of the primary advantages of these units is the cost savings they offer. By reusing solvents, companies can reduce their expenses on purchasing new ones, ultimately leading to substantial savings over time.

3. Improved Product Quality

Solvent recovery ensures the purity of solvents, which can have a direct impact on the quality of the final products in industries like pharmaceuticals and chemicals. High-purity solvents contribute to better product consistency and reliability.

IV. Applications of Solvent Recovery Distillation Units

Solvent recovery distillation units find applications in a wide range of industries, including:

1. Pharmaceutical Industry

In pharmaceutical manufacturing, maintaining the integrity of solvents is critical for producing safe and effective medications. Solvent recovery distillation units ensure the highest quality solvents for drug formulation.

2. Chemical Manufacturing

Chemical processes often involve the use of various solvents. These units allow chemical manufacturers to recover and reuse solvents, promoting sustainability and cost-efficiency.

3. Research and Development

Research laboratories and institutions benefit from solvent recovery distillation units by minimizing solvent waste and optimizing resources for experimentation.

V. Choosing the Right Solvent Recovery Distillation Unit

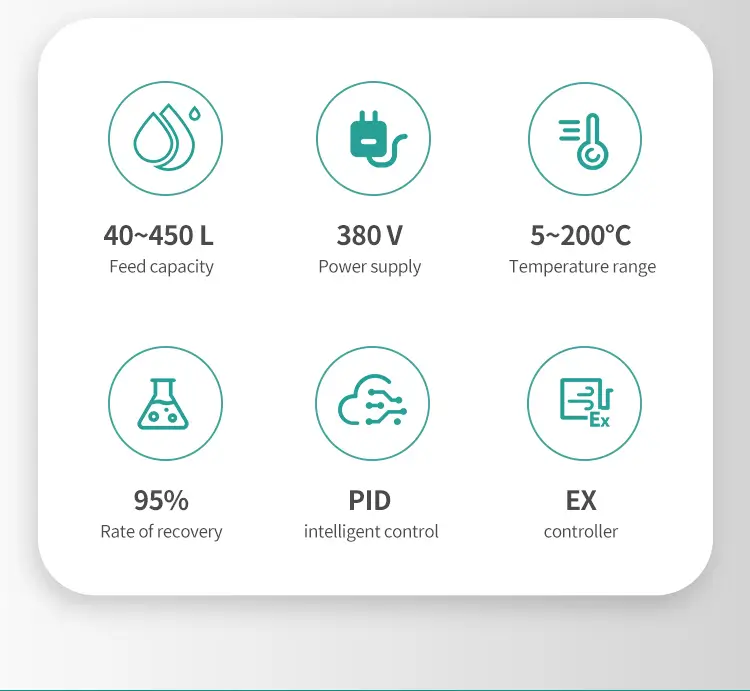

Selecting the appropriate solvent recovery distillation unit for your specific needs is crucial. Consider factors such as the type of solvents used, production volume, and space availability. Consulting with experts in the field can help you make an informed decision.

VI. Conclusion

Solvent recovery distillation units have become indispensable in modern industrial processes, offering environmental benefits, cost savings, and improved product quality. Understanding how these units work and their diverse applications can help industries make informed choices in adopting this sustainable and efficient technology. As the world continues to prioritize eco-friendly practices, solvent recovery distillation units are poised to play an even more significant role in shaping the future of industrial processes.

| Model | T-40 | T-60 | T-80 | T-90 | T-125 |

| Feed Capacity (L) | 40 | 60 | 80 | 90 | 125 |

| Heating Component Power (KW) | 4.0 | 4.0 | 5.0 | 5.0 | 6.0 |

| Electric Fan Power (KW) | 0.09 | 0.12 | 0.12 | 0.12 | 0.12 |

| Maximum Power (KW) | 4.5 | 4.5 | 5.5 | 5.5 | 6.5 |

| Maximum Current (A) | 6.9 | 6.9 | 8.4 | 8.4 | 10 |

| supply Voltage (ACV/HZ) | 3-phase 5-line 380/50-60 | ||||

| Control Voltage (ACVHZ) | 220/50-60 | ||||

| Heating Method | Hot medium oil indirect heating | ||||

| Length (mm) | 950 | 1100 | 1100 | 1100 | 1150 |

| Width (mm) | 750 | 750 | 850 | 850 | 850 |

| Height (mm) | 1200 | 1200 | 1260 | 1260 | 1435 |

| Weight (kg) | 140 | 160 | 250 | 260 | 300 |

| operate Temperature (℃) | 50~210 | ||||

| The Best Ambient Temperature For The Machine To Run (℃) | 5~35 | ||||

| Noise (dB) | 65 | ||||

| Recovery Ratio | 95% | ||||

| Recovery Time | 2.5~3.0 | 2.5~3.0 | 2.5~3.0 | 2.5~3.0 | 3.0~3.5 |

FAQ

Q: What is the primary purpose of solvent recovery distillation units?

A: Solvent recovery distillation units are designed to efficiently recover and reuse solvents used in industrial processes, reducing waste and saving resources.

Q: How do solvent recovery distillation units work?

A: These units use a distillation process to separate solvents from other substances by heating the solvent mixture, causing the solvents to vaporize, and then condensing them back into liquid form.

Q: What are the key benefits of using solvent recovery distillation units?

A: The benefits include environmental advantages by reducing solvent waste and emissions, significant cost savings through solvent reuse, and improved product quality due to high-purity solvents.

Q: In which industries are solvent recovery distillation units commonly used?

A: Solvent recovery distillation units find applications in pharmaceutical manufacturing, chemical industries, research and development laboratories, and various other sectors where solvents are utilized.

Q: How can I choose the right solvent recovery distillation unit for my needs?

A: When selecting a unit, consider factors such as the types of solvents used, production volume, and available space. Consulting experts in the field can provide valuable guidance in making the best choice for your specific requirements.