In today’s world, sustainability is no longer just a buzzword; it’s a necessity. Industries across the globe are continuously seeking innovative ways to reduce their environmental footprint and maximize resource efficiency. One such advancement in this endeavor is the use of ethanol recycling equipment. Ethanol recycling equipment plays a crucial role in various industries, helping them reduce waste, save costs, and promote eco-friendly practices.

1. Understanding Ethanol Recycling Equipment

Ethanol recycling equipment refers to a range of machinery and processes designed to recover and purify ethanol from various sources. This equipment is particularly prevalent in industries where ethanol is used as a solvent, fuel, or as part of the manufacturing process. Ethanol recycling aims to maximize the efficiency of ethanol use while minimizing waste and environmental impact.

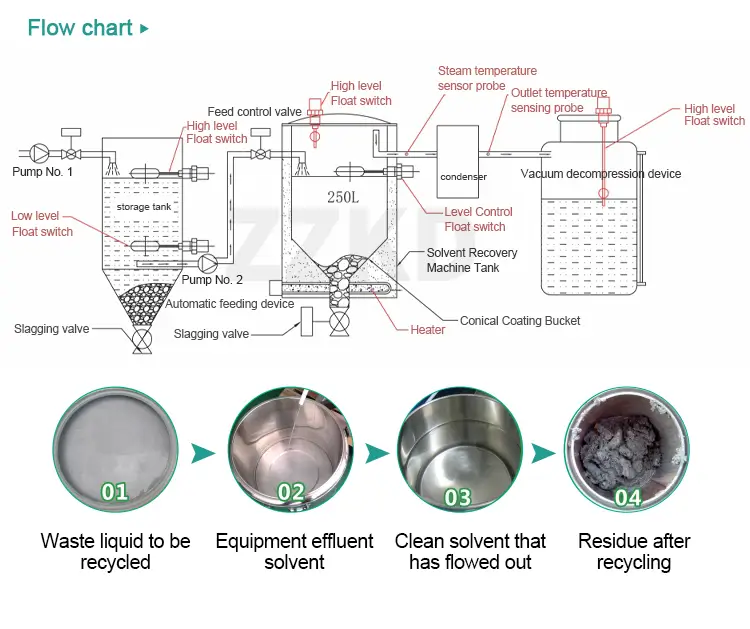

2. How Ethanol Recycling Works

Ethanol recycling equipment operates on the principle of distillation. It takes advantage of the differences in boiling points between ethanol and other substances, such as water or impurities, to separate and recover pure ethanol. The process involves heating the mixture to vaporize the ethanol, then condensing it back into liquid form. This separation allows for the recovery of ethanol, which can then be reused.

3. Ethanol Recycling Applications

The applications of ethanol recycling equipment are diverse, spanning various industries:

- Biofuel Production: In the biofuel industry, ethanol recycling equipment is used to recover ethanol from fermentation processes, making it available for reuse as a biofuel component.

- Pharmaceuticals: Pharmaceutical companies use ethanol as a solvent. Recycling equipment ensures that high-quality ethanol is consistently available for manufacturing medicines.

- Beverage Industry: Ethanol recycling is crucial for breweries and distilleries, where it helps recover and purify ethanol used in brewing and distillation processes.

- Chemical Manufacturing: Ethanol is a common reagent in chemical synthesis. Recycling equipment reduces the need for fresh ethanol and minimizes chemical waste.

4. Benefits of Ethanol Recycling Equipment

The adoption of ethanol recycling equipment yields several noteworthy benefits:

- Cost Savings: Recycling ethanol reduces the need for purchasing fresh ethanol, resulting in significant cost savings for industries.

- Reduced Environmental Impact: By reusing ethanol and minimizing waste, industries can lower their environmental footprint and contribute to sustainability efforts.

- Consistent Quality: Ethanol recycling equipment ensures that the recovered ethanol is of high quality and suitable for various applications.

- Regulatory Compliance: Many industries are subject to stringent environmental regulations. Ethanol recycling equipment helps companies meet these standards.

5. Ethanol Recycling Equipment Varieties

There are various types of ethanol recycling equipment available, including:

- Distillation Columns: These columns facilitate the separation of ethanol from other compounds through fractional distillation.

- Membrane Filtration: Membrane-based systems use selective permeability to separate ethanol from impurities.

- Adsorption Technologies: Adsorption processes use specific materials to capture ethanol and release it when needed.

6. Considerations for Ethanol Recycling

Before implementing ethanol recycling equipment, industries should consider factors such as the purity required, production volume, and the specific application. Customized solutions may be necessary to meet the unique needs of each industry.

Conclusion

Ethanol recycling equipment is a vital tool in promoting sustainability and resource efficiency across multiple industries. Its ability to recover and purify ethanol not only saves costs but also contributes to environmental conservation. As industries continue to prioritize eco-friendly practices, the adoption of ethanol recycling equipment is likely to become even more widespread, leading to a greener and more sustainable future.

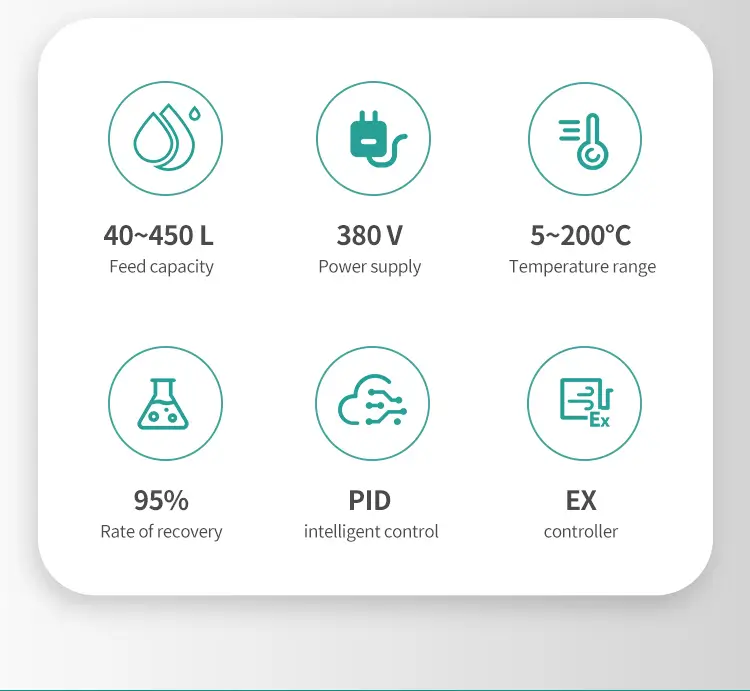

| Model | T-40 | T-60 | T-80 | T-90 | T-125 |

| Feed Capacity (L) | 40 | 60 | 80 | 90 | 125 |

| Heating Component Power (KW) | 4.0 | 4.0 | 5.0 | 5.0 | 6.0 |

| Electric Fan Power (KW) | 0.09 | 0.12 | 0.12 | 0.12 | 0.12 |

| Maximum Power (KW) | 4.5 | 4.5 | 5.5 | 5.5 | 6.5 |

| Maximum Current (A) | 6.9 | 6.9 | 8.4 | 8.4 | 10 |

| supply Voltage (ACV/HZ) | 3-phase 5-line 380/50-60 | ||||

| Control Voltage (ACVHZ) | 220/50-60 | ||||

| Heating Method | Hot medium oil indirect heating | ||||

| Length (mm) | 950 | 1100 | 1100 | 1100 | 1150 |

| Width (mm) | 750 | 750 | 850 | 850 | 850 |

| Height (mm) | 1200 | 1200 | 1260 | 1260 | 1435 |

| Weight (kg) | 140 | 160 | 250 | 260 | 300 |

| operate Temperature (℃) | 50~210 | ||||

| The Best Ambient Temperature For The Machine To Run (℃) | 5~35 | ||||

| Noise (dB) | 65 | ||||

| Recovery Ratio | 95% | ||||

| Recovery Time | 2.5~3.0 | 2.5~3.0 | 2.5~3.0 | 2.5~3.0 | 3.0~3.5 |

FAQ

Q: What is ethanol recycling equipment?

A: Ethanol recycling equipment is machinery designed to recover and purify ethanol from various sources, reducing waste and costs.

Q: In which industries is ethanol recycling equipment commonly used?

A: Ethanol recycling equipment is prevalent in biofuel, pharmaceutical, beverage, and chemical industries, among others.

Q: How does ethanol recycling equipment work?

A: It operates on the principle of distillation, separating ethanol from other substances through differences in boiling points.

Q: What are the key benefits of using ethanol recycling equipment?

A: Benefits include cost savings, reduced environmental impact, consistent quality, and compliance with regulatory standards.

Q: Are there different types of ethanol recycling equipment available?

A: Yes, there are various types, including distillation columns, membrane filtration, and adsorption technologies, tailored to different industry needs.