Introduction Of Ultrasonic Cell Crusher:

Ultrasonic cell crushers, also known as ultrasonic homogenizer machine, are scientific instruments used for the disruption, lysis, and extraction of biological samples. They utilize high-frequency sound waves, typically in the ultrasonic range (20 kHz to 100 kHz), to break down cells and release their contents.

ultrasonic cell crusher homogenizer machine

Structural Composition Of Ultrasonic Cell Crusher:

Ultrasonic Generator:

This is the main control unit that generates high-frequency electrical signals. It provides the power source for the ultrasonic homogenizer machine.

Transducer:

The ultrasonic homogenizer machine is connected to a transducer, which converts the electrical signals into mechanical vibrations. Transducers can be either piezoelectric or magnetostrictive, depending on the specific design of the instrument.

Ultrasonic Horn or Probe:

The transducer is coupled to an ultrasonic horn or probe. The horn/probe is usually made of a high-strength material such as titanium or stainless steel. It amplifies and transfers the mechanical vibrations from the transducer to the sample.

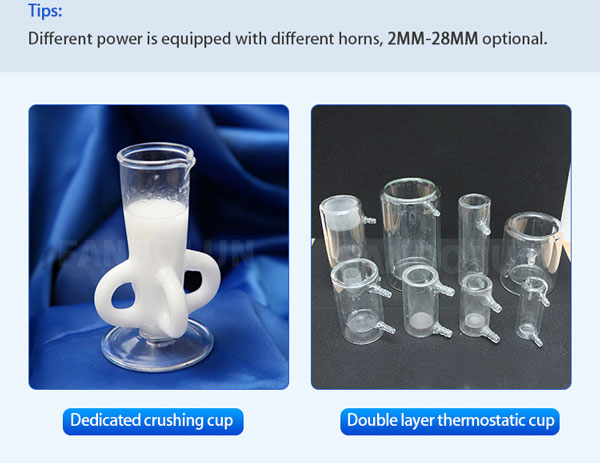

Sample Chamber:

The sample chamber is where the biological samples or substances to be pulverized are placed. It is typically a tube or vessel made of a material compatible with the sample, such as glass or plastic. The sample chamber may have different sizes or volumes to accommodate various sample quantities.

Cooling System:

Some ultrasonic homogenizer machines may include a cooling system to prevent excessive heating during the process. This can be crucial for maintaining the integrity of sensitive samples or avoiding thermal damage.

Control Panel:

The control panel is usually located on the front of the instrument. It allows users to set and adjust various parameters, such as power output, treatment time, and operating modes. The control panel may include buttons, knobs, digital displays, and other interface elements for user interaction.

Safety Features:

Ultrasonic homogenizer machines often come equipped with safety features to protect the user and the instrument. These may include safety interlocks, overheating protection, and alarms to ensure safe operation.

Advantages Of Ultrasonic Cell Crusher:

Efficient and fast cell disruption:

The strong cavitation generated by high-frequency sound waves will destroy the cell membrane, thereby effectively extracting proteins, nucleic acids, organelles and other intracellular components. The process is usually quick, with cell disruption occurring within minutes, saving time compared to other methods.

Versatility:

Can be used with a variety of sample types, including animal tissue, plant tissue, bacteria, yeast, and other microorganisms. Furthermore, they can handle different sample sizes, from small-scale experiments to large-scale industrial processes.

Non-contact and non-destructive:

Unlike mechanical methods such as grinding or shear force, ultrasonic homogenizer machine is a non-contact technique. There is no physical contact between the instrument and the sample, minimizing the risk of contamination and reducing sample loss. Additionally, the non-destructive nature of sonication helps protect delicate molecules, such as enzymes or proteins, that might be easily denatured or degraded by other methods.

Adjustable Power and Processing Parameters:

Ultrasonic cell disruptors often offer adjustable power settings, allowing the user to control the intensity of the ultrasound. This feature is useful when working with different sample types as it can be optimized for specific cell disruption requirements.

Scalability:

Ultrasonic cell disruptors are available in a variety of sizes and capacities, making them suitable for both laboratory-scale experiments and industrial-scale applications. They can be easily scaled up or down depending on sample volume and processing requirements.

Application Of Ultrasonic Cell Crusher:

Molecular Biology:

The high-frequency sound waves efficiently disrupt cells, releasing nucleic acids for downstream analysis, such as PCR, cloning, sequencing, and gene expression studies. They are also employed in chromatin immunoprecipitation (ChIP) assays to extract DNA-protein complexes.

Cell Biology:

Ultrasonic homogenizer machine find applications in cell biology studies, facilitating the disruption and lysis of cells to access intracellular components. They are utilized in experiments involving the isolation of organelles, extraction of proteins, analysis of cellular signaling pathways, and investigation of cellular structures. Ultrasonic disruption is also employed in cell-based assays, such as flow cytometry, where intact single-cell suspensions are required.

Microbiology:

In microbiology, ultrasonic homogenizer machine are used for the disruption and lysis of microorganisms such as bacteria, yeast, and fungi. They aid in the extraction of intracellular components, including proteins, enzymes, and metabolites, for characterization and analysis.

Biochemistry:

Ultrasonic homogenizer machines are indispensable tools in biochemistry research. They are used for sample preparation, enabling the efficient extraction of proteins, lipids, and other biomolecules from tissues, cells, or microbial cultures.

Ultrasonic Cell Crusher Maintenance

- No preheating is required, and good grounding should be used.

- The horn selection switch is used to match the frequency and impedance of the horns of different specifications and the consistency of the generator. If the frequency of the transducer assembly does not match the impedance of the generator, the ultrasound will not work.

- The temperature protection setting point must be higher than the room temperature or sample temperature by more than 5°C. When temperature protection occurs, press SET for more than 4 seconds to reset the protection value. When setting the wrong temperature, you can also press the SET button for more than 4 seconds to reset.

- After a certain period of time, the end of the horn will be corroded by cavitation and become hairy. It can be smoothed with oil stone or file, otherwise it will affect the working effect.

- It is strictly forbidden to start the machine when the horn is not inserted into the liquid (no load), otherwise the transducer or ultrasonic generator will be damaged.

- The ultrasonic homogenizer machine should be placed in a dry place without humidity, direct sunlight and corrosive gas.

- During ultrasonic crushing, due to the cavitation effect of ultrasonic waves in the liquid, the temperature of the liquid will rise rapidly, and users should pay more attention to the temperature of various cells. It is recommended to use multiple breaks in a short time (no more than 5 seconds each time), and at the same time, an ice bath can be added for cooling.

- Multiple jobs in a short time, the working time is 1-2 seconds, and the gap time is 1-2 seconds, which is better than continuous long-term work. To prevent the liquid from heating up, a longer gap time can be set.

- Ultrasonic homogenizer machine adopts switching power supply without power frequency transformer. After opening the generator casing, do not touch it randomly to prevent electric shock. The performance of this instrument is reliable, and it is generally not easy to be damaged.

Model Ultrasonic Frequency (KHZ)

Maximum Power Optional

probe(Φmm)Crusher Capacity Sample temperature monitor UH-150W 20-25 0-150 W 2,3,6 0.1-150ml Yes UH-250W 20-25 0-250 W 2,3,6,8 0.1-250ml Yes UH-500W 20-25 0-500 W 2,3,6,8,10, 0.1-500ml Yes UH-650W 20-25 0-650 W 2,3,6,10,12, 0.1-650ml Yes UH-900W 20-25 0-900 W 2,3,6,8,10,12 0.1-900ml Yes UH-950W 20-25 0-950 W 2,3,6,10,12,15 0.1-950ml Yes UH-1200W 19.5-20.5 0-1200 W 3,6,10,15,20,22 5-1200ml Yes UH-1500W 19.5-20.5 0-1500 W 10,15,20,22,25 20-1500ml Yes UH-1800W 19.5-20.5 0-1800 W 15,20,22,25 50-1800ml Yes UH-2000W 19.5-20.5 0-2000 W 15,20,22,25 50-2000ml Yes UH-2200W 19.5-20.5 0-2200 W 15,20,22,25 50-2200ml Yes

FAQ

Q:1. How to choose the instrument parameters reasonably?

A:The power of different types of equipment is different. The size of the power determines the size range of the horn used. The scale of the horn is adjusted to the scale of the equipment. The size of the horn determines the throughput. In general, choose 3mm for less than 5ml, 6-8mm for 5-50ml, and 10mm or more horn for more than 50ml. Don’t care about the duty cycle, it mainly refers to the ratio of ultrasonic time to pause time.

Q:Why use plastic large test tubes instead of glass tubes?

A:Glass tubes may shatter if used instead of plastic test tubes. Ultrasound is an elastic mechanical wave in a material medium, which is both a wave form and an energy form. The effect of the instrument on cells mainly includes thermal effect, cavitation effect and mechanical effect.

Q:What should I do when the sonic cell pulverizer does not work properly?

A:1. First check whether the horn (ultrasonic probe) of the ultrasonic cell pulverizer is fully in contact with the sample. During the operation, the ultrasonic probe needs to be immersed at least 2cm below the liquid surface of the sample, which is required by the principle of ultrasound. Do not form a no-load situation, otherwise it will damage the host and cause the ultrasonic waves to not be sent out normally.