Introduction Of Mini Spray Dryer Machine

A Mini spray dryer is a device used to dry small amounts of liquid. It works by atomizing liquid into small droplets, which are then dried with hot air in a drying chamber. The process, known as spray drying, is used in a wide variety of industries, including pharmaceuticals, food and chemicals.

Important Parameters:

- Air inlet temperature: room temperature to 300°C.

- Air outlet temperature: room temperature to 140°C.

- Moisture evaporation: 0-2000ml/h.

- Stainless steel nozzle: Nozzle diameter Φ0.75mm, equipped with a nozzle through the needle to prevent clogging, the frequency of the needle through can be adjusted freely.

- Heat source: electricity.

- Control system: embedded intelligent control system.

- Real-time temperature control (PID control): error ±1℃.

- Fan: 0.75kW (aluminum alloy booster).

- Maximum drying air volume: 105m³/h.

Advantages Of Mini Spray Dryer Machine:

Cost-effective:

Mini spray dryers are generally less expensive than larger spray dryers, making them a more cost-effective solution for R&D labs, pilot plants and small-scale production.

Small volume:

The Mini spray dryer’s compact size and small footprint make it ideal for use in smaller laboratories or facilities with limited space.

Ease of use:

The Mini spray dryer is relatively easy to use and requires minimal training, making it a popular choice for small laboratories or facilities with limited staffing resources.

Flexibility:

The Mini spray dryer can be used to produce a wide range of powders and granules including food ingredients, pharmaceuticals and chemicals.

Quick drying:

Mini spray dryer can quickly dry solutions and suspensions into fine powder or granules, which is beneficial for the production of heat-sensitive materials.

Easy to clean:

The Mini spray dryer is easy to clean and maintain, helping to reduce downtime and increase productivity.

Minimum Sample Requirements:

The Mini spray dryer requires only a small amount of material, which is great when dealing with expensive or rare materials.

Reproducibility:

Small spray dryers provide good reproducibility of the drying process, which is crucial for R&D studies.

Applications Of Mini Spray Dryer Machine:

In the pharmaceutical industry

Spray dryer machine is used to produce dry powder from liquid pharmaceutical preparations.

In the food industry

Small spray dryers are used to produce powdered ingredients such as milk powder, coffee powder and protein powder. Spray dryer machines are also used to produce flavor and aroma compounds used in various foods.

In the chemical industry

Small spray dryers are used in the production of catalysts, pigments and other specialty chemicals. Spray dryer machines are also used to produce ceramic powders, which are used in a variety of applications including electronic components and fuel cells.

Maintenance Guide:

Regular cleaning:

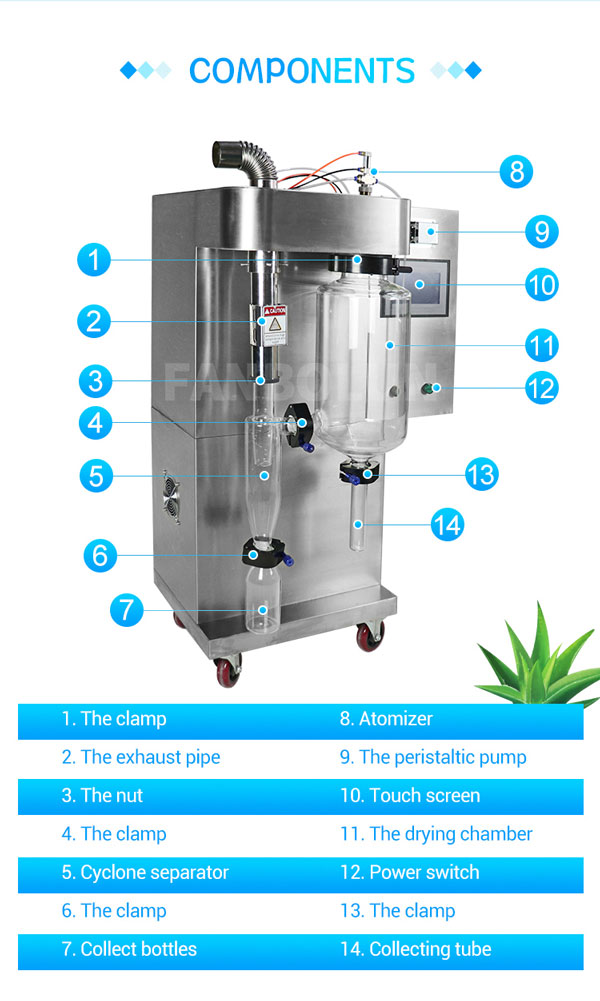

The spray drying chamber, cyclone separator, and other components should be cleaned regularly to prevent buildup of residual material, which can affect dryer performance. Follow ZZKD cleaning recommendations and use only approved cleaners.

Inspect and Replace Parts:

Periodically inspect the Spray dryer machine for signs of wear and damage. Replace any worn or damaged parts, such as nozzles or filters, as needed to keep your dryer functioning properly.

Lubrication:

Regularly lubricate spray dryer components such as bearings and motors.

Calibration:

Regular calibration of spray dryer operating parameters, such as temperature and flow rate, helps ensure accurate and consistent performance.

Safety inspections:

Regular safety inspections, such as checking for leaks and ensuring that all safety features, such as pressure relief valves, are functioning properly.

Recordkeeping:

Record all maintenance activities, including cleanings, inspections, and repairs, to help identify potential problems and ensure your dryer is properly maintained.

Regular Maintenance:

Follow ZZKD’s recommended spray dryer machine maintenance schedule, which may include regular maintenance and replacement parts to help extend the life of your equipment.

Parameter

| Model | Inlet temperature

(°C) |

Moisture maximum evaporation (kg/h) | Rotating speed (r.p.m) | Diameter of spray

disc (mm) |

Electric heating

power (kw) |

| LPG-5 | 140-350 | 5 | 25000 | 50 | 9 |

| LPG-10 | 140-350 | 10 | 25000 | 50 | 20 |

| LPG-25 | 140-350 | 25 | 18000 | 100 | 36 |

| LPG-50 | 140-350 | 50 | 18000 | 120 | 63 |

| LPG-100 | 140-350 | 100 | 18000 | 140 | 81 |

| LPG-150 | 140-350 | 150 | 15000 | 150 | 99 |

| LPG-200-2000 | 140-350 | 200-2000 | 8000-15000 | 180-340 | According to

the actual situation |

| Model | Inlet temperature

(°C) |

Moisture maximum evaporation (kg/h) | Rotating speed (r.p.m) |

| LPG-5 | 140-350 | 5 | 25000 |

| LPG-10 | 140-350 | 10 | 25000 |

| LPG-25 | 140-350 | 25 | 18000 |

| LPG-50 | 140-350 | 50 | 18000 |

| LPG-100 | 140-350 | 100 | 18000 |

| LPG-150 | 140-350 | 150 | 15000 |

| LPG-200-2000 | 140-350 | 200-2000 | 8000-15000 |

FAQ

Q: Poor powder quality is a common problem that small spray dryers may encounter. This may manifest as uneven particle size, low bulk density or powder agglomeration.

A: First, check the nozzle to make sure it is clean and not clogged, which can cause uneven particle size or clumping. Also, check the atomization pressure and adjust as needed to ensure a consistent and even spray. Finally, ensure that the drying temperature and airflow are appropriate for the specific product being dried.

Q: The nozzles of small spray dryers can become clogged with product or debris, resulting in an uneven or inconsistent spray pattern.

A: To solve this problem, the nozzle should be cleaned regularly to prevent clogging. This can be done by soaking the nozzle in a cleaning solution or using compressed air to blow out any debris that may be clogging the nozzle.

Q: Drying chamber leaks can lead to inefficient drying and product loss.

A: To fix this, check the drying chamber and all connections to make sure they are tight. If a leak is found, repair or replace any damaged or worn parts to prevent further leaks.